Description

ICA-30 Air-Cooled Industrial Chiller

Overview

Air cooled chiller is an efficient and energy-saving refrigeration equipment that achieves heat exchange through an air-cooled condenser without the need for an additional water cooling system. It is suitable for scenarios where water resources are scarce or installation space is limited. The cooling capacity of this unit is 30 horsepower (approximately 105000 BTU/h), which can provide a stable cooling source for commercial buildings, office buildings, hospitals, schools and other places.

Key Advantages

Efficient and stable: using advanced compressors and air cooling technology to adapt to high temperature environments and ensure continuous cooling;

Energy saving and environmental protection: using environmentally friendly refrigerants, low energy consumption design, in line with green and energy-saving standards;

Intelligent and convenient: equipped with microcomputer control, supporting remote monitoring and automatic adjustment, easy to operate;

Flexible installation: No need for cooling towers or water pipelines, modular design facilitates transportation and site adaptation.

The unit has low operating noise and low maintenance costs, making it an ideal choice for air conditioning systems in modern buildings.

Product Overview

This series of air-cooled industrial chillers is designed specifically for the cooling needs of medium and large industries. It adopts air cooling condensation technology, which does not require additional cooling towers or circulating water systems. It is easy to install and has low maintenance costs. The core components of the unit are selected from internationally renowned brands, combined with efficient and energy-saving design, suitable for industrial scenarios such as plastic molding, electroplating oxidation, chemical reactions, laser processing, pharmaceutical storage, etc. that require precise temperature control, providing stable and reliable low-temperature circulating water solutions.

Key Features

Energy-Efficient Performance

Scroll compressor and microchannel heat exchanger enhance energy efficiency.

Intelligent capacity modulation adjusts power output based on real-time demands.

Robust Reliability

Hermetically sealed refrigeration system operates in -15℃~45℃ ambient temperatures.

Multi-layer protection (overvoltage, phase failure, anti-freeze) ensures durable operation.

Eco-Friendly Intelligence

R410A refrigerant complies with global environmental standards.

7″ touchscreen + remote monitoring enables real-time control and predictive maintenance.

Flexible Installation

Compact design supports outdoor installation with small footprint.

Pre-assembled pump, tank, and piping for rapid deployment.

Applications

Plastics/Rubber: Injection molding, extrusion line cooling

Surface Treatment: Electroplating bath, oxidation tank temperature control

Laser Processing: Laser cutter, welding equipment cooling

Pharmaceuticals: Reactor cooling, low-temperature storage

Data Centers: Precision temperature control for server rooms

Support Services

Customization: Tailored solutions for specific process requirements

Specifications

| Model Item | ICA-0.6 | ICA-1 | ICA-2 | ICA-3 | ICA-5 | ICA-6 | ICA-8 | ICA-10 | ||

| Performance parameter | ||||||||||

| Cooling capacity | kW | 1.6 | 2.7 | 5.2 | 9.1 | 15.0 | 18.0 | 23.0 | 29.5 | |

| 10³kcal/h | 1.4 | 2.3 | 4.5 | 7.8 | 12.9 | 15.5 | 19.8 | 25.4 | ||

| Power source | V/ph/Hz | 220/1/50 | 380/3/50 | |||||||

| Power input | kW | 0.9 | 1.2 | 2.2 | 2.9 | 5.3 | 6.5 | 8.4 | 10.5 | |

| Current | A | 4.6 | 5.9 | 11.3 | 8.2 | 11.7 | 12.2 | 20.0 | 23.4 | |

| Main component | ||||||||||

| Compressor | Type | Rotor type | Scroll type | |||||||

| Power | kW | 0.5 | 0.8 | 1.6 | 2.3 | 4.2 | 5.1 | 6.9 | 8.7 | |

|

Pump | Power | kW | 0.25 | 0.25 | 0.37 | 0.37 | 0.55 | 0.75 | 0.75 | 0.75 |

| Head | m | 36 | 34 | 26 | 24 | 28 | 33 | 30 | 27 | |

| Flow | m³/h | 0.28 | 0.46 | 0.89 | 1.6 | 2.6 | 3.1 | 4.0 | 5.1 | |

| L/min | 4.6 | 7.7 | 14.8 | 26.7 | 43.3 | 51.7 | 66.0 | 85.0 | ||

| Tank capacity | L | 12 | 20 | 35 | 60 | 70 | 70 | 100 | 135 | |

| Pipe size/Noise/Weight/Dimension | ||||||||||

| Pipe size | DN | 15 | 20 | 25 | 40 | |||||

| Noise | dB(A) | 56 | 58 | 58 | 60 | 61 | 62 | 64 | 65 | |

| Weight | kg | 50 | 68 | 108 | 140 | 185 | 210 | 260 | 310 | |

| Dim. | L | mm | 420 | 500 | 600 | 680 | 750 | 750 | 1350 | 1510 |

| W | mm | 420 | 500 | 600 | 680 | 750 | 750 | 680 | 750 | |

| H | mm | 815 | 950 | 1160 | 1360 | 1480 | 1480 | 1360 | 1480 | |

| Model Item | ICA-12 | ICA-15 | ICA-20 | ICA-25 | ICA-30 | ICA-40 | ICA-50 | ICA-60 | ||

| Performance parameter | ||||||||||

| Cooling capacity | kW | 35 | 44 | 58.5 | 69.0 | 86.0 | 116.0 | 140.0 | 168.0 | |

| 10³kcal/h | 30.1 | 37.8 | 50.3 | 59.3 | 74.1 | 100.0 | 120.0 | 145.0 | ||

| Power source | V/ph/Hz | 380/3/50 | ||||||||

| Power input | kW | 12.5 | 15.0 | 21.1 | 24.0 | 30.0 | 41.3 | 48.0 | 58.5 | |

| Current | A | 24.0 | 27.7 | 41.7 | 46.7 | 57.0 | 76.0 | 88.0 | 110.0 | |

| Main component | ||||||||||

| Compressor | type | Scroll type | ||||||||

| Power | kW | 10.1 | 12.5 | 17.4 | 20.2 | 25.0 | 34.8 | 40.6 | 50.0 | |

|

Pump | Power | kW | 1.2 | 1.2 | 2.2 | 2.2 | 2.2 | 3.5 | 3.5 | 4.0 |

| Head | m | 29 | 27 | 27 | 26 | 25 | 34 | 29 | 25 | |

| Flow | m³/h | 6.0 | 7.6 | 10.0 | 11.8 | 14.8 | 20.0 | 24.0 | 28.9 | |

| L/min | 100 | 127 | 167 | 197 | 247 | 333 | 400 | 480 | ||

| Tank capacity | L | 135 | 155 | 230 | 230 | 230 | 300 | 300 | 300 | |

| Pipe size/Noise/Weight/Dimension | ||||||||||

| Pipe size | DN | 40 | 50 | 65 | ||||||

| Noise | dB(A) | 65 | 66 | 67 | 68 | 68 | 69 | 69 | 69 | |

| Weight | kg | 340 | 415 | 620 | 670 | 780 | 1100 | 1300 | 1500 | |

| Dim. | L | mm | 1510 | 1785 | 2080 | 2080 | 2080 | 2200 | 3000 | 3400 |

| W | mm | 750 | 915 | 1050 | 1050 | 1050 | 1200 | 1200 | 1200 | |

| H | mm | 1480 | 1630 | 1820 | 1820 | 1910 | 2135 | 2120 | 2135 | |

*With the technological progress,we will periodically update products.Please follow KANSA website.

Technological innovationWe never stop innovating…

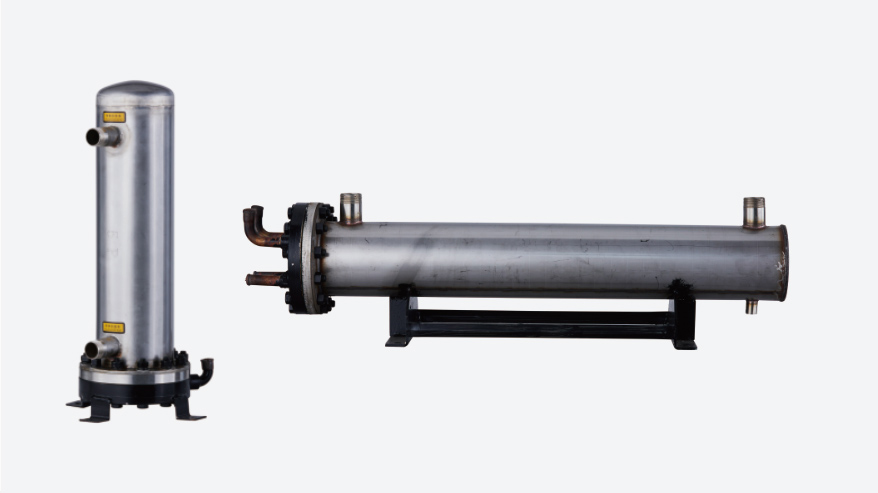

Stainless steel shell and tube evaporator

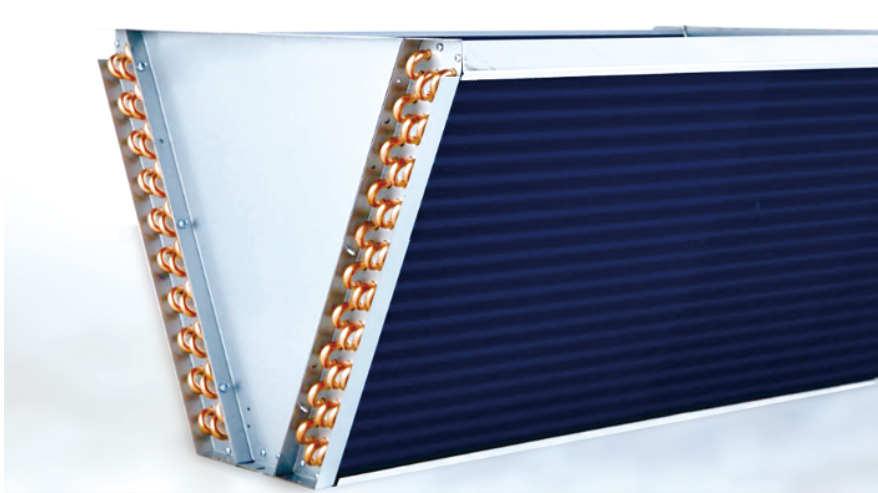

Stainless steel shell and tube evaporator I nnovative V-shaped fin condenser

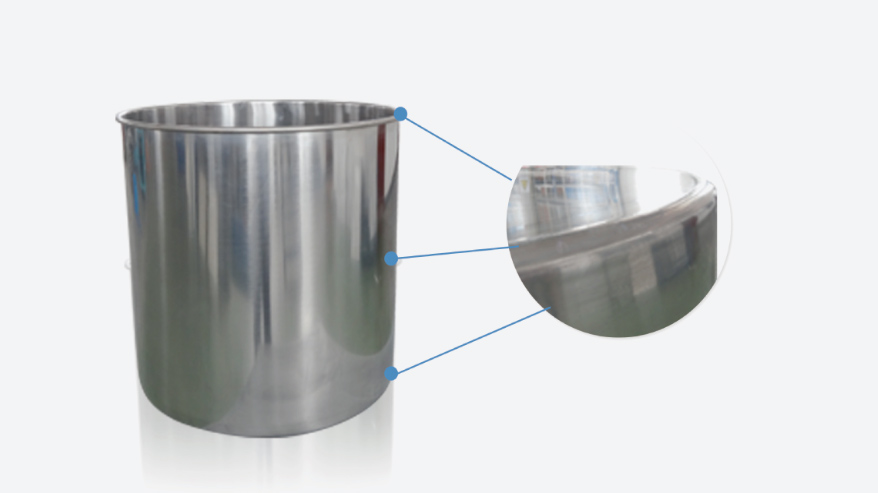

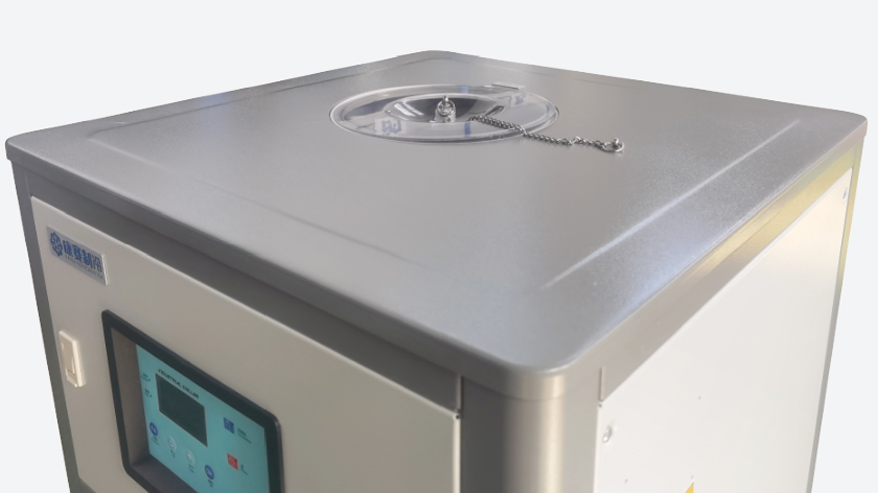

I nnovative V-shaped fin condenser Innovative new cylindrical water tank

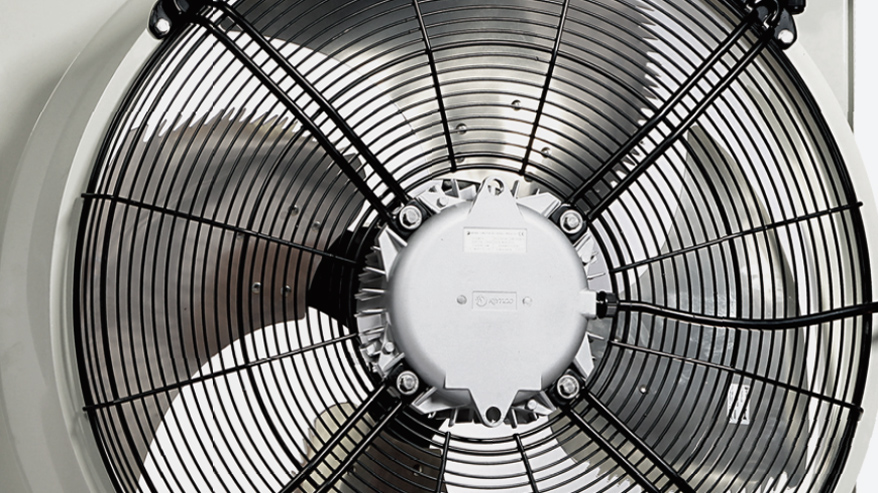

Innovative new cylindrical water tank High efficiency and low noise fan

High efficiency and low noise fan Intelligent touch screen controller

Intelligent touch screen controller High precision controller

High precision controller

Copper tube with internal thread

Copper tube with internal thread Sinusoidal heat transfer fins

Sinusoidal heat transfer fins Electric expansion PID technology

Electric expansion PID technology Innovative refrigerant distribution technology

Innovative refrigerant distribution technology Professional air flow channel design

Professional air flow channel design Air volume automatic control

Air volume automatic control

Over temperature protection

Over temperature protection Current protection

Current protection Self-diagnosis

Self-diagnosis Intelligent antifreeze

Intelligent antifreeze Water flow alarm

Water flow alarm Water level alarm

Water level alarm Pressure alarm

Pressure alarm Timing switch on and off

Timing switch on and off

Famous brand compressor

Famous brand compressor Imported brand accessories

Imported brand accessories Keep improving everywhere

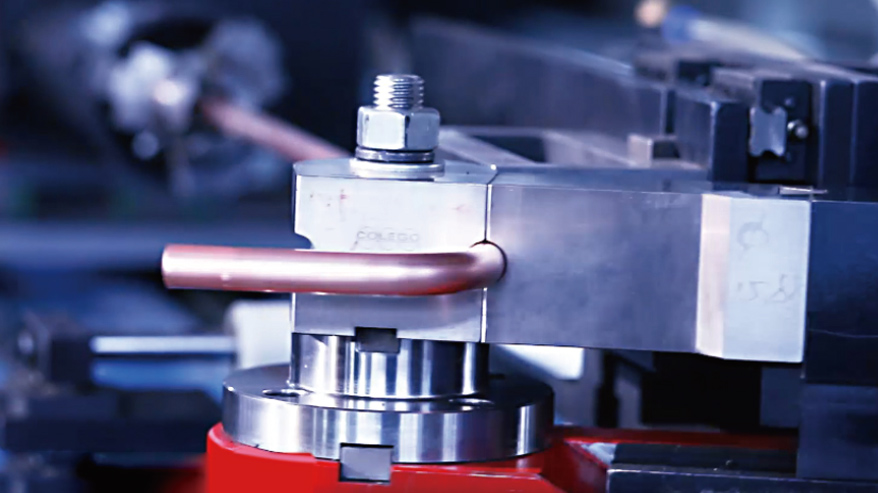

Keep improving everywhere 3D pipe bending machine

3D pipe bending machine Automatic refrigerant adding machine

Automatic refrigerant adding machine Automatic welding machine

Automatic welding machine

Sheet metal precision drawing

Sheet metal precision drawing Drawing forming guide ring

Drawing forming guide ring Robot bending machine

Robot bending machine Laser welding

Laser welding Automatic cutting machine

Automatic cutting machine Automatic joint welding

Automatic joint welding