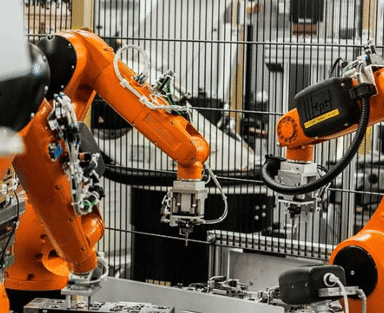

Application of Cooling Equipment Units in Robotics Industry

Background of Application

With the rapid development of technology, robotics is increasingly applied in industrial production. From precise assembly lines to high-intensity welding tasks, robots are gradually replacing humans in performing various complex and dangerous tasks. However, high-performance robotic equipment generates a significant amount of heat during operation. If this heat is not dispersed in a timely manner, it can lead to decreased equipment performance, increased failure rates, and even shortened equipment lifespan. Therefore, the application of cooling equipment units in the field of robotics is particularly important.

Main Application Scenarios

- Precision Assembly Robots: In precision assembly operations, robots require extremely high precision and stability. Cooling equipment units regulate the internal temperature of robots to ensure that all components operate under optimal conditions, thereby improving assembly accuracy and efficiency.

- Welding Robots: Welding processes generate a large amount of heat, and welding robots are no exception. Cooling equipment units effectively reduce the temperature in the working area of welding robots, preventing overheating and ensuring welding quality and the stability of robot operation.

- Heavy-Duty Robots: When heavy-duty robots are lifting heavy loads, their motors and transmission components generate significant heat. Cooling equipment units ensure that the temperature of these components remains within a reasonable range, improving the robots’ carrying capacity and operational efficiency.

- Robot Control Systems: The control system is the “brain” of robot operation and is highly sensitive to temperature. Cooling equipment units ensure that the control system operates in a stable temperature environment, avoiding instability or failures caused by temperature fluctuations.

Key Advantages :

- Efficient Heat Dissipation: Cooling equipment units employ advanced heat dissipation technology to quickly dissipate the heat generated inside robots, ensuring optimal operation.

- Improved Stability: By regulating temperature, cooling equipment units reduce performance variations in robots caused by temperature fluctuations, enhancing stability and reliability.

- Extended Lifespan: Proper temperature control reduces wear and aging of robot components, thereby extending equipment lifespan.

- Energy-Saving and Environmentally Friendly: Modern cooling equipment units are typically designed for high efficiency and energy savings, reducing energy consumption and environmental pollution while ensuring heat dissipation effectiveness.