Description

ICA-20&25 Air-Cooled Chillers

Air-cooled chillers are efficient and convenient cooling solutions widely used in commercial buildings, industrial facilities, and large public spaces. They utilize air-cooled condensers to exchange heat directly with ambient air, eliminating the need for cooling towers and water circulation systems. This results in flexible installation, easy maintenance, and strong environmental adaptability.

Core Advantages

High Efficiency & Stability: Equipped with advanced scroll compressors and high-efficiency fin-type condensers, combined with intelligent control systems, ensuring stable operation across varying conditions and rapid response to cooling demands.

Eco-Friendly & Energy-Saving: Compatible with eco-friendly refrigerants (eg., R410A), complying with international environmental standards. Select models feature inverter technology for precise energy adjustment and reduced operating costs.

Quiet Operation: Optimized fan and airflow design, integrated with noise-reducing materials, minimizes operational noise, making it suitable for noise-sensitive environments.

Smart Control: Microcomputer control panel supports remote monitoring and fault alerts, simplifying maintenance and enhancing operational efficiency.

Application Scenarios

20HP Model: Ideal for small to medium-sized spaces such as offices, retail stores, and small data centers, meeting standard cooling requirements.

25HP Model: Suited for larger areas or higher cooling loads, including large supermarkets, hospitals, and industrial workshops, delivering enhanced cooling capacity.

Design Features

Modular design ensures compact structure and small footprint, allowing flexible installation outdoors or in well-ventilated areas. The casing is made of rust-resistant and corrosion-proof materials, suitable for harsh climates.

ICA-15: 15HP Air-Cooled Industrial Chiller

Abstract:

The ICA-15 offers a large cooling capacity of 44kW, ideal for cooling large industrial equipment. Its air-cooled design eliminates the need for an additional cooling water source, providing flexibility and ease of installation. It also offers various precision options to meet the needs of different equipment. The 155L water tank ensures a continuous water supply to maintain production efficiency.

Product Introduction:

The ICA-15 air-cooled industrial chiller, developed by Kangsai Refrigeration, is designed for cooling large industrial equipment. With a cooling capacity of 44kW, it can handle high-load environments efficiently. The air-cooled design eliminates the need for additional cooling water sources, reducing overall operating costs and making installation more flexible. Multiple precision options (±0.1℃/±0.5℃/±1.5℃) allow precise temperature control for various equipment types. The 155L large-capacity water tank ensures a stable water supply, reduces downtime, and enhances production efficiency. Kangsai Refrigeration is trusted for its expert technology and quality service.

Selling Points:

- Large cooling capacity, suitable for large industrial equipment

- Air-cooled design, no need for an additional cooling water source, offering flexibility and convenience

Advantages:

- Easy installation without complex cooling systems

- Multiple precision options to meet specific equipment needs

- Large-capacity water tank to ensure long-term water supply

Points of Concern to Customers:

- Efficient cooling for large equipment

- Low initial investment cost

- Convenient maintenance

Specifications

| Model Item | ICA-0.6 | ICA-1 | ICA-2 | ICA-3 | ICA-5 | ICA-6 | ICA-8 | ICA-10 | ||

| Performance parameter | ||||||||||

| Cooling capacity | kW | 1.6 | 2.7 | 5.2 | 9.1 | 15.0 | 18.0 | 23.0 | 29.5 | |

| 10³kcal/h | 1.4 | 2.3 | 4.5 | 7.8 | 12.9 | 15.5 | 19.8 | 25.4 | ||

| Power source | V/ph/Hz | 220/1/50 | 380/3/50 | |||||||

| Power input | kW | 0.9 | 1.2 | 2.2 | 2.9 | 5.3 | 6.5 | 8.4 | 10.5 | |

| Current | A | 4.6 | 5.9 | 11.3 | 8.2 | 11.7 | 12.2 | 20.0 | 23.4 | |

| Main component | ||||||||||

| Compressor | Type | Rotor type | Scroll type | |||||||

| Power | kW | 0.5 | 0.8 | 1.6 | 2.3 | 4.2 | 5.1 | 6.9 | 8.7 | |

|

Pump | Power | kW | 0.25 | 0.25 | 0.37 | 0.37 | 0.55 | 0.75 | 0.75 | 0.75 |

| Head | m | 36 | 34 | 26 | 24 | 28 | 33 | 30 | 27 | |

| Flow | m³/h | 0.28 | 0.46 | 0.89 | 1.6 | 2.6 | 3.1 | 4.0 | 5.1 | |

| L/min | 4.6 | 7.7 | 14.8 | 26.7 | 43.3 | 51.7 | 66.0 | 85.0 | ||

| Tank capacity | L | 12 | 20 | 35 | 60 | 70 | 70 | 100 | 135 | |

| Pipe size/Noise/Weight/Dimension | ||||||||||

| Pipe size | DN | 15 | 20 | 25 | 40 | |||||

| Noise | dB(A) | 56 | 58 | 58 | 60 | 61 | 62 | 64 | 65 | |

| Weight | kg | 50 | 68 | 108 | 140 | 185 | 210 | 260 | 310 | |

| Dim. | L | mm | 420 | 500 | 600 | 680 | 750 | 750 | 1350 | 1510 |

| W | mm | 420 | 500 | 600 | 680 | 750 | 750 | 680 | 750 | |

| H | mm | 815 | 950 | 1160 | 1360 | 1480 | 1480 | 1360 | 1480 | |

| Model Item | ICA-12 | ICA-15 | ICA-20 | ICA-25 | ICA-30 | ICA-40 | ICA-50 | ICA-60 | ||

| Performance parameter | ||||||||||

| Cooling capacity | kW | 35 | 44 | 58.5 | 69.0 | 86.0 | 116.0 | 140.0 | 168.0 | |

| 10³kcal/h | 30.1 | 37.8 | 50.3 | 59.3 | 74.1 | 100.0 | 120.0 | 145.0 | ||

| Power source | V/ph/Hz | 380/3/50 | ||||||||

| Power input | kW | 12.5 | 15.0 | 21.1 | 24.0 | 30.0 | 41.3 | 48.0 | 58.5 | |

| Current | A | 24.0 | 27.7 | 41.7 | 46.7 | 57.0 | 76.0 | 88.0 | 110.0 | |

| Main component | ||||||||||

| Compressor | type | Scroll type | ||||||||

| Power | kW | 10.1 | 12.5 | 17.4 | 20.2 | 25.0 | 34.8 | 40.6 | 50.0 | |

|

Pump | Power | kW | 1.2 | 1.2 | 2.2 | 2.2 | 2.2 | 3.5 | 3.5 | 4.0 |

| Head | m | 29 | 27 | 27 | 26 | 25 | 34 | 29 | 25 | |

| Flow | m³/h | 6.0 | 7.6 | 10.0 | 11.8 | 14.8 | 20.0 | 24.0 | 28.9 | |

| L/min | 100 | 127 | 167 | 197 | 247 | 333 | 400 | 480 | ||

| Tank capacity | L | 135 | 155 | 230 | 230 | 230 | 300 | 300 | 300 | |

| Pipe size/Noise/Weight/Dimension | ||||||||||

| Pipe size | DN | 40 | 50 | 65 | ||||||

| Noise | dB(A) | 65 | 66 | 67 | 68 | 68 | 69 | 69 | 69 | |

| Weight | kg | 340 | 415 | 620 | 670 | 780 | 1100 | 1300 | 1500 | |

| Dim. | L | mm | 1510 | 1785 | 2080 | 2080 | 2080 | 2200 | 3000 | 3400 |

| W | mm | 750 | 915 | 1050 | 1050 | 1050 | 1200 | 1200 | 1200 | |

| H | mm | 1480 | 1630 | 1820 | 1820 | 1910 | 2135 | 2120 | 2135 | |

*With the technological progress,we will periodically update products.Please follow KANSA website.

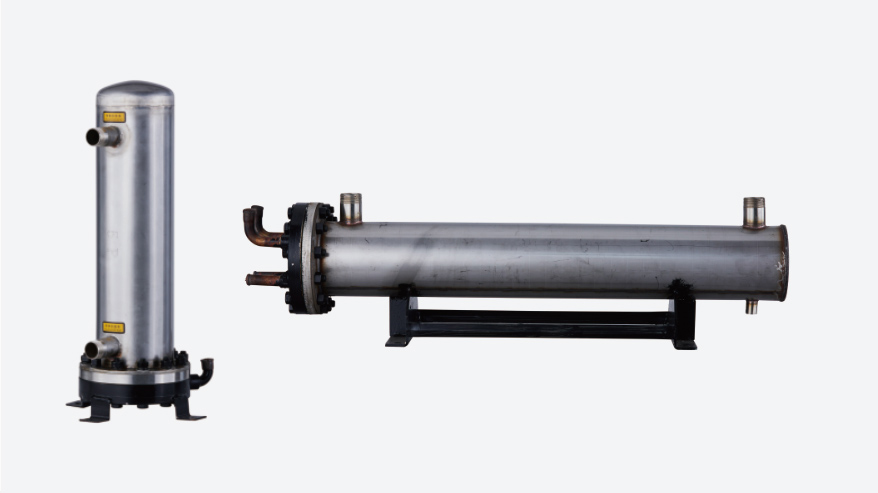

Stainless steel shell and tube evaporator

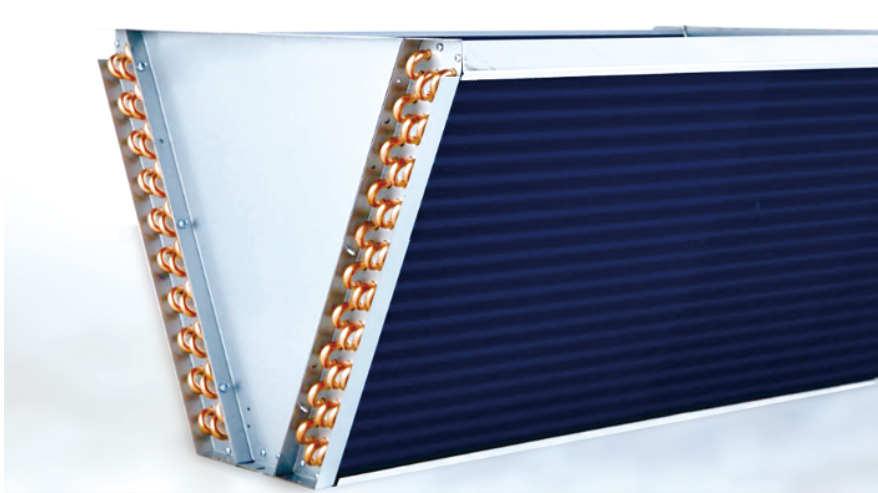

Stainless steel shell and tube evaporator I nnovative V-shaped fin condenser

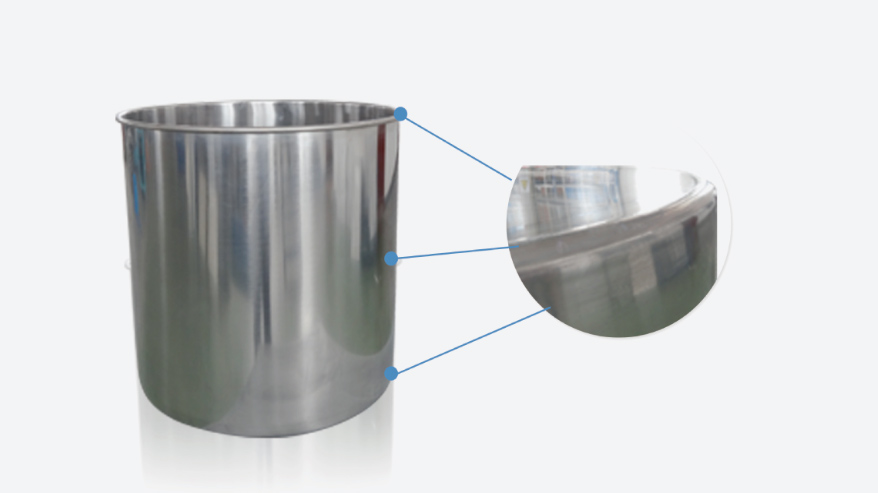

I nnovative V-shaped fin condenser Innovative new cylindrical water tank

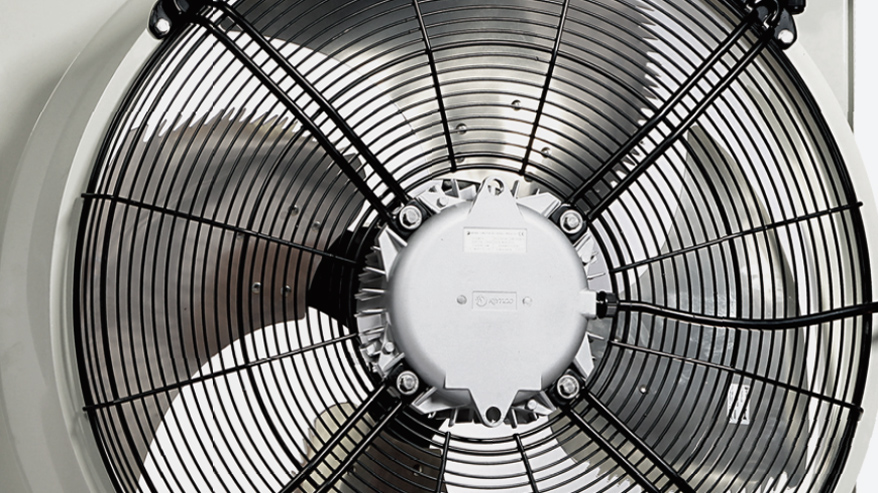

Innovative new cylindrical water tank High efficiency and low noise fan

High efficiency and low noise fan Intelligent touch screen controller

Intelligent touch screen controller High precision controller

High precision controller

Copper tube with internal thread

Copper tube with internal thread Sinusoidal heat transfer fins

Sinusoidal heat transfer fins Electric expansion PID technology

Electric expansion PID technology Innovative refrigerant distribution technology

Innovative refrigerant distribution technology Professional air flow channel design

Professional air flow channel design Air volume automatic control

Air volume automatic control

Over temperature protection

Over temperature protection Current protection

Current protection Self-diagnosis

Self-diagnosis Intelligent antifreeze

Intelligent antifreeze Water flow alarm

Water flow alarm Water level alarm

Water level alarm Pressure alarm

Pressure alarm Timing switch on and off

Timing switch on and off

Famous brand compressor

Famous brand compressor Imported brand accessories

Imported brand accessories Keep improving everywhere

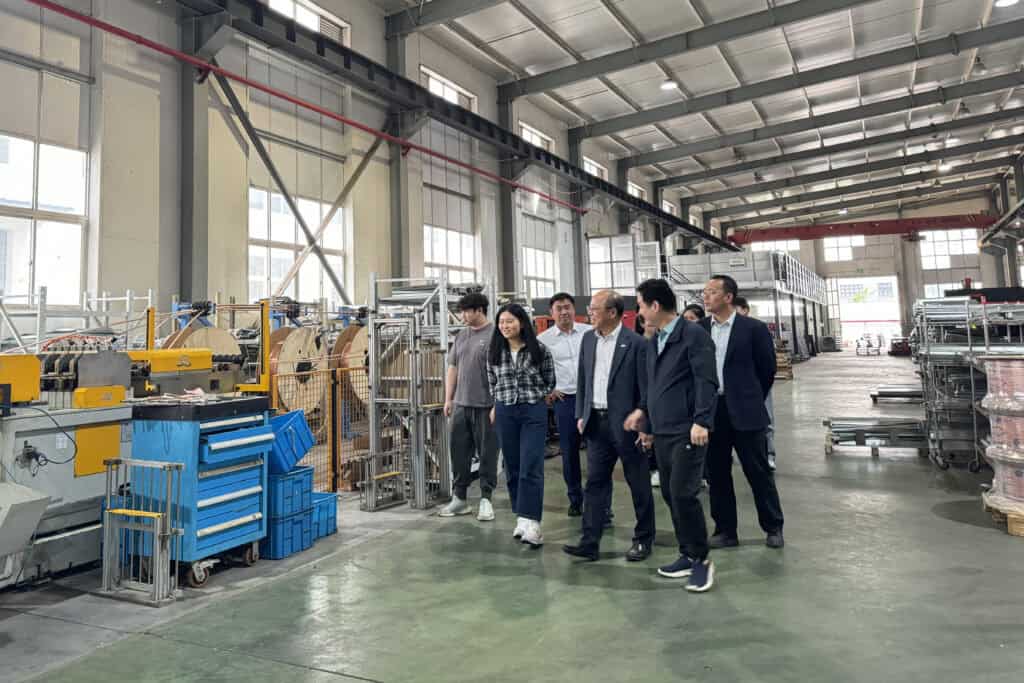

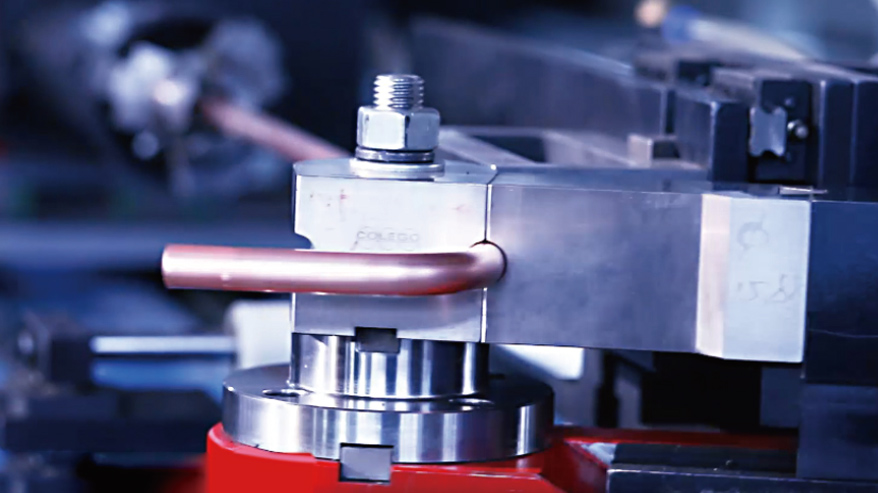

Keep improving everywhere 3D pipe bending machine

3D pipe bending machine Automatic refrigerant adding machine

Automatic refrigerant adding machine Automatic welding machine

Automatic welding machine

Sheet metal precision drawing

Sheet metal precision drawing Drawing forming guide ring

Drawing forming guide ring Robot bending machine

Robot bending machine Laser welding

Laser welding Automatic cutting machine

Automatic cutting machine Automatic joint welding

Automatic joint welding