Description

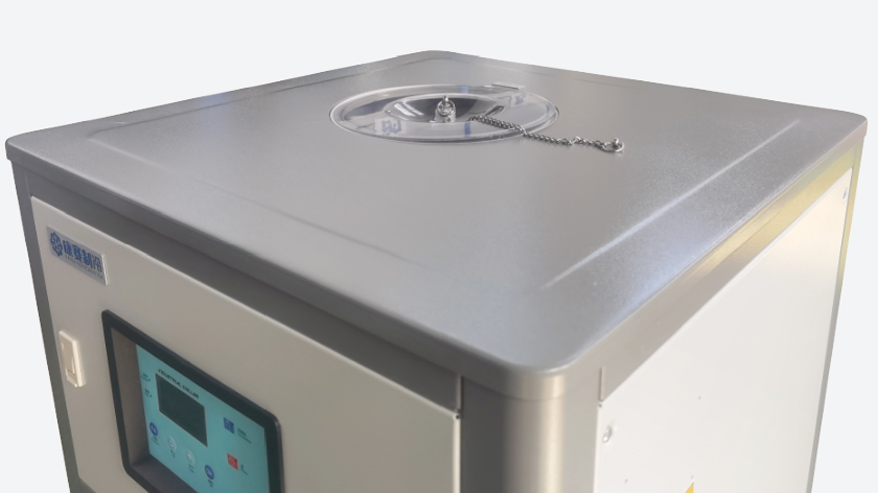

ICA-3 Air-Cooled Industrial Chiller

This product is a 3 HP air-cooled industrial chiller designed for industrial scenarios requiring larger cooling capacities. Utilizing air-cooling technology, it eliminates the need for water-cooling systems and achieves efficient heat dissipation through forced ventilation, offering flexible and convenient installation. Its core function is to provide stable and reliable low-temperature circulating cooling for various industrial equipment, suitable for long-term high-load operation.

Basic features include:

Air-cooled design: No cooling tower or dedicated machine room required, adapting to complex industrial environments;

Modular construction: Supports multi-unit parallel expansion for future scalability;

Intelligent control: Equipped with a basic temperature control interface for start/stop and temperature setting;

Environmental adaptation: Suitable for working environments ranging from room temperature to high temperature, dust-proof design enhances durability.

Typical applications include:

Large CNC machine tool spindle cooling

Plastic extruder molding temperature control

Continuous laser cutting equipment cooling

Chemical reactor temperature stabilization systems

Food freezing production lines

The device is easy to maintain, requiring only periodic cleaning of the heat sink and ventilation checks, making it suitable for small to medium-sized industrial users without specialized maintenance staff.

Specifications

| Model Item | ICA-0.6 | ICA-1 | ICA-2 | ICA-3 | ICA-5 | ICA-6 | ICA-8 | ICA-10 | ||

| Performance parameter | ||||||||||

| Cooling capacity | kW | 1.6 | 2.7 | 5.2 | 9.1 | 15.0 | 18.0 | 23.0 | 29.5 | |

| 10³kcal/h | 1.4 | 2.3 | 4.5 | 7.8 | 12.9 | 15.5 | 19.8 | 25.4 | ||

| Power source | V/ph/Hz | 220/1/50 | 380/3/50 | |||||||

| Power input | kW | 0.9 | 1.2 | 2.2 | 2.9 | 5.3 | 6.5 | 8.4 | 10.5 | |

| Current | A | 4.6 | 5.9 | 11.3 | 8.2 | 11.7 | 12.2 | 20.0 | 23.4 | |

| Main component | ||||||||||

| Compressor | Type | Rotor type | Scroll type | |||||||

| Power | kW | 0.5 | 0.8 | 1.6 | 2.3 | 4.2 | 5.1 | 6.9 | 8.7 | |

|

Pump | Power | kW | 0.25 | 0.25 | 0.37 | 0.37 | 0.55 | 0.75 | 0.75 | 0.75 |

| Head | m | 36 | 34 | 26 | 24 | 28 | 33 | 30 | 27 | |

| Flow | m³/h | 0.28 | 0.46 | 0.89 | 1.6 | 2.6 | 3.1 | 4.0 | 5.1 | |

| L/min | 4.6 | 7.7 | 14.8 | 26.7 | 43.3 | 51.7 | 66.0 | 85.0 | ||

| Tank capacity | L | 12 | 20 | 35 | 60 | 70 | 70 | 100 | 135 | |

| Pipe size/Noise/Weight/Dimension | ||||||||||

| Pipe size | DN | 15 | 20 | 25 | 40 | |||||

| Noise | dB(A) | 56 | 58 | 58 | 60 | 61 | 62 | 64 | 65 | |

| Weight | kg | 50 | 68 | 108 | 140 | 185 | 210 | 260 | 310 | |

| Dim. | L | mm | 420 | 500 | 600 | 680 | 750 | 750 | 1350 | 1510 |

| W | mm | 420 | 500 | 600 | 680 | 750 | 750 | 680 | 750 | |

| H | mm | 815 | 950 | 1160 | 1360 | 1480 | 1480 | 1360 | 1480 | |

| Model Item | ICA-12 | ICA-15 | ICA-20 | ICA-25 | ICA-30 | ICA-40 | ICA-50 | ICA-60 | ||

| Performance parameter | ||||||||||

| Cooling capacity | kW | 35 | 44 | 58.5 | 69.0 | 86.0 | 116.0 | 140.0 | 168.0 | |

| 10³kcal/h | 30.1 | 37.8 | 50.3 | 59.3 | 74.1 | 100.0 | 120.0 | 145.0 | ||

| Power source | V/ph/Hz | 380/3/50 | ||||||||

| Power input | kW | 12.5 | 15.0 | 21.1 | 24.0 | 30.0 | 41.3 | 48.0 | 58.5 | |

| Current | A | 24.0 | 27.7 | 41.7 | 46.7 | 57.0 | 76.0 | 88.0 | 110.0 | |

| Main component | ||||||||||

| Compressor | type | Scroll type | ||||||||

| Power | kW | 10.1 | 12.5 | 17.4 | 20.2 | 25.0 | 34.8 | 40.6 | 50.0 | |

|

Pump | Power | kW | 1.2 | 1.2 | 2.2 | 2.2 | 2.2 | 3.5 | 3.5 | 4.0 |

| Head | m | 29 | 27 | 27 | 26 | 25 | 34 | 29 | 25 | |

| Flow | m³/h | 6.0 | 7.6 | 10.0 | 11.8 | 14.8 | 20.0 | 24.0 | 28.9 | |

| L/min | 100 | 127 | 167 | 197 | 247 | 333 | 400 | 480 | ||

| Tank capacity | L | 135 | 155 | 230 | 230 | 230 | 300 | 300 | 300 | |

| Pipe size/Noise/Weight/Dimension | ||||||||||

| Pipe size | DN | 40 | 50 | 65 | ||||||

| Noise | dB(A) | 65 | 66 | 67 | 68 | 68 | 69 | 69 | 69 | |

| Weight | kg | 340 | 415 | 620 | 670 | 780 | 1100 | 1300 | 1500 | |

| Dim. | L | mm | 1510 | 1785 | 2080 | 2080 | 2080 | 2200 | 3000 | 3400 |

| W | mm | 750 | 915 | 1050 | 1050 | 1050 | 1200 | 1200 | 1200 | |

| H | mm | 1480 | 1630 | 1820 | 1820 | 1910 | 2135 | 2120 | 2135 | |

*With the technological progress,we will periodically update products.Please follow KANSA website.

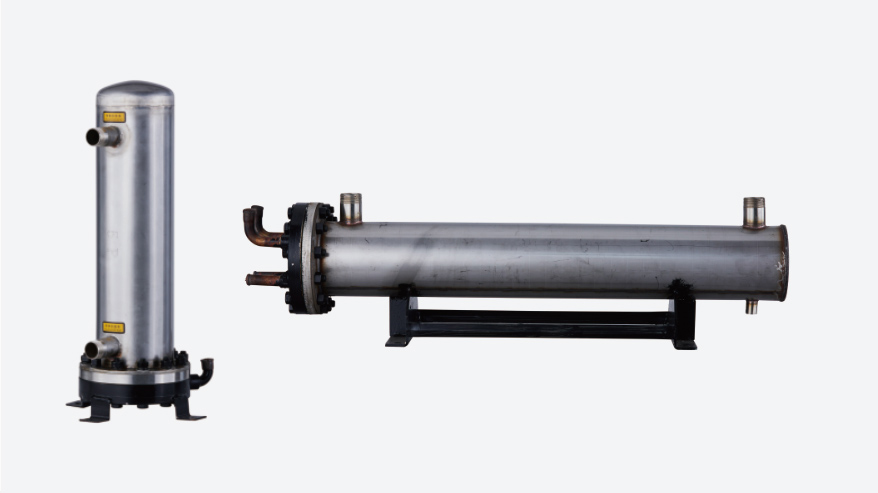

Stainless steel shell and tube evaporator

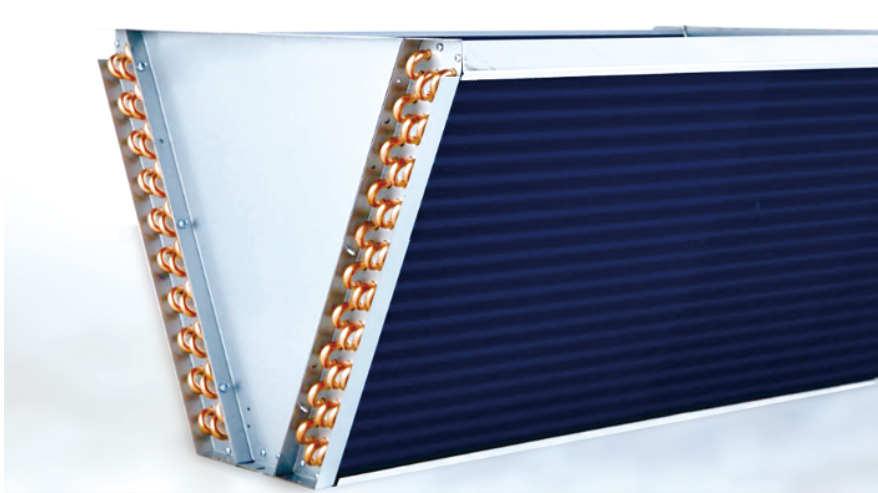

Stainless steel shell and tube evaporator I nnovative V-shaped fin condenser

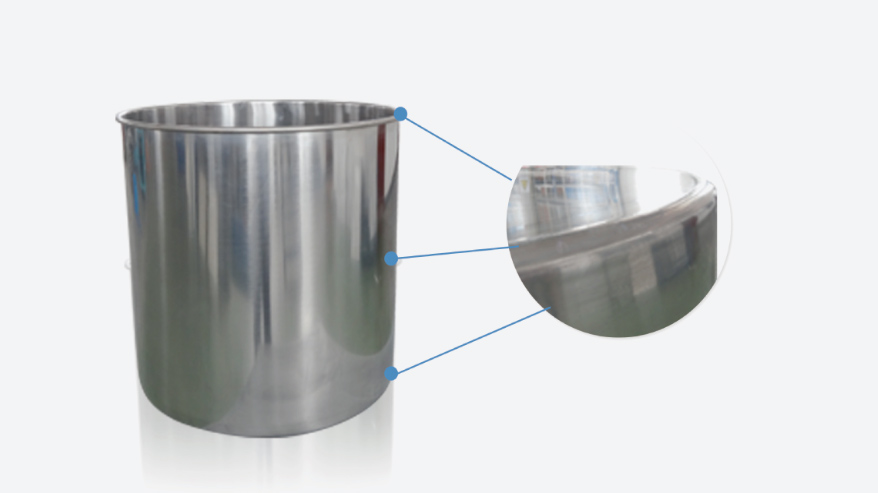

I nnovative V-shaped fin condenser Innovative new cylindrical water tank

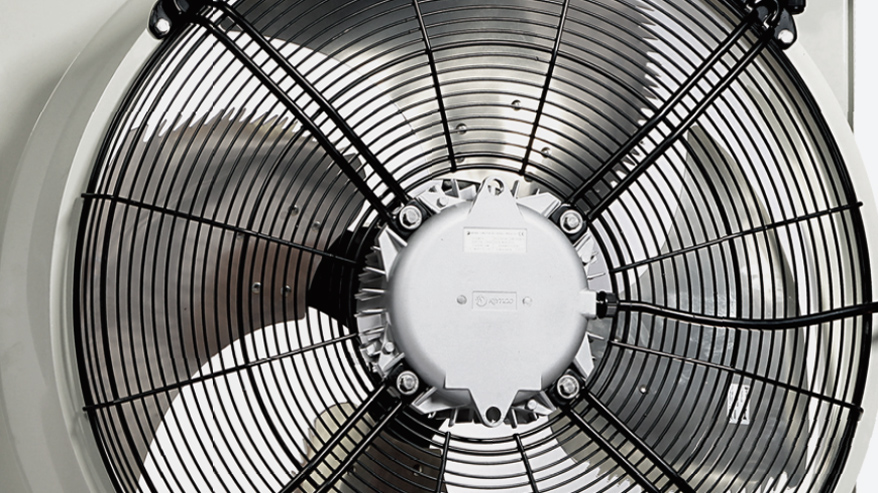

Innovative new cylindrical water tank High efficiency and low noise fan

High efficiency and low noise fan Intelligent touch screen controller

Intelligent touch screen controller High precision controller

High precision controller

Copper tube with internal thread

Copper tube with internal thread Sinusoidal heat transfer fins

Sinusoidal heat transfer fins Electric expansion PID technology

Electric expansion PID technology Innovative refrigerant distribution technology

Innovative refrigerant distribution technology Professional air flow channel design

Professional air flow channel design Air volume automatic control

Air volume automatic control

Over temperature protection

Over temperature protection Current protection

Current protection Self-diagnosis

Self-diagnosis Intelligent antifreeze

Intelligent antifreeze Water flow alarm

Water flow alarm Water level alarm

Water level alarm Pressure alarm

Pressure alarm Timing switch on and off

Timing switch on and off

Famous brand compressor

Famous brand compressor Imported brand accessories

Imported brand accessories Keep improving everywhere

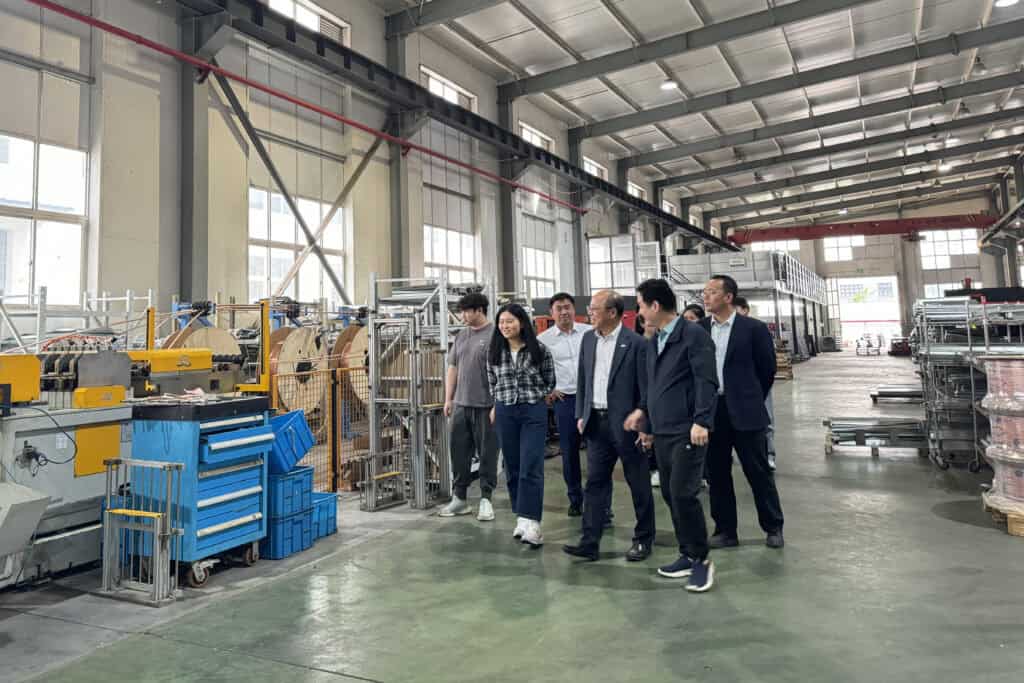

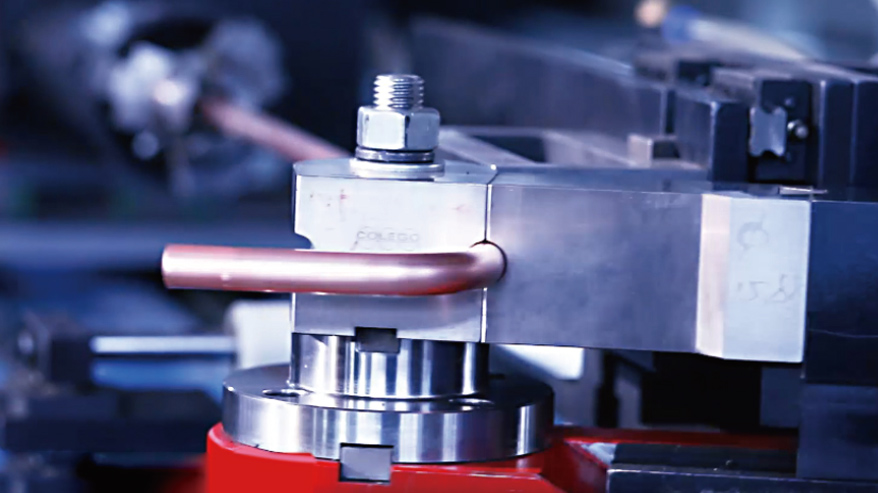

Keep improving everywhere 3D pipe bending machine

3D pipe bending machine Automatic refrigerant adding machine

Automatic refrigerant adding machine Automatic welding machine

Automatic welding machine

Sheet metal precision drawing

Sheet metal precision drawing Drawing forming guide ring

Drawing forming guide ring Robot bending machine

Robot bending machine Laser welding

Laser welding Automatic cutting machine

Automatic cutting machine Automatic joint welding

Automatic joint welding