Description

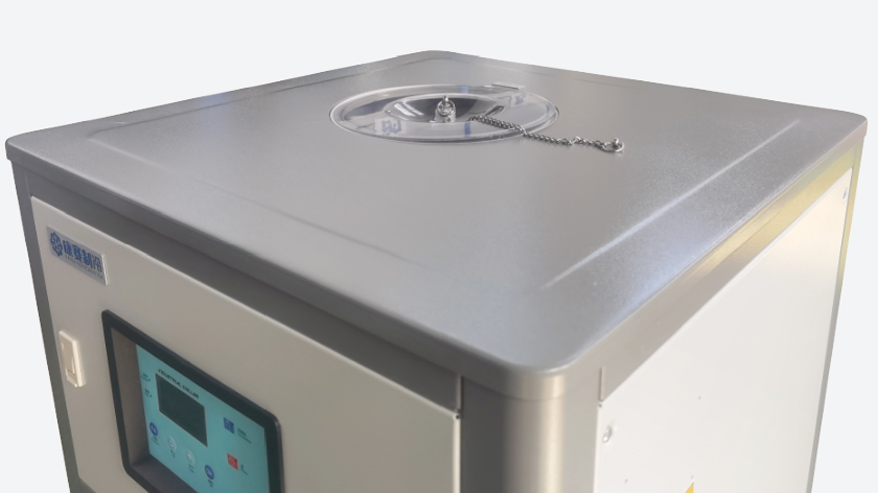

ICA-5&6 Air-Cooled Industrial Chillers

This series of air-cooled industrial chillers includes 5 HP and 6 HP models, designed for medium and large-scale industrial cooling needs. Utilizing air-cooling technology, the devices achieve efficient heat exchange through high-volume fans and optimized heat sink structures, eliminating the need for water-cooling systems or dedicated machine rooms, significantly reducing installation complexity and operational costs. Their core function is to provide stable and continuous low-temperature circulating cooling solutions for various industrial equipment, suitable for long-term high-load operation scenarios.

Basic Functional Features

Air-Cooled Design Advantages

No requirement for cooling towers, circulating water circuits, or water treatment equipment, adapting to industrial environments with water scarcity or space constraints;

Rapid heat dissipation via forced air convection allows flexible deployment outdoors or in open workshops.

Modular Architecture

Both 5 HP and 6 HP models adopt standardized designs, supporting multi-unit parallel or series expansion to adjust cooling capacity as needed;

Key components feature removable modular structures for easy maintenance and upgrades.

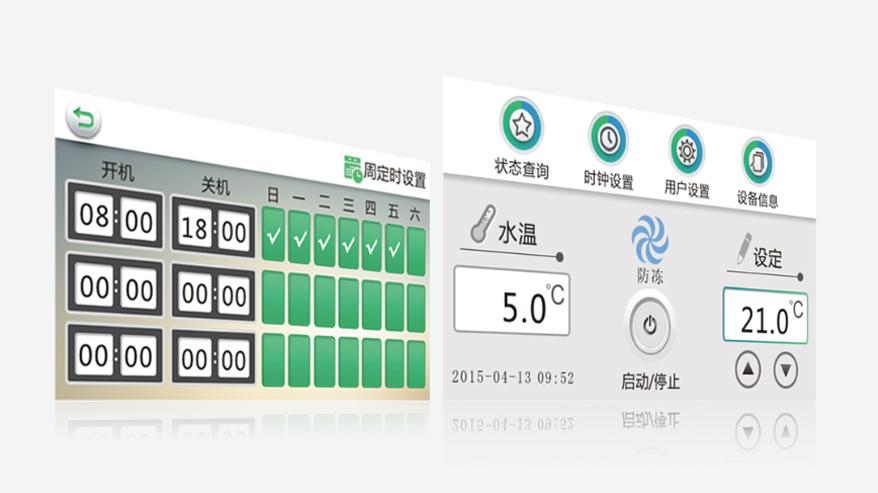

Intelligent Control System

Equipped with a basic temperature control panel supporting temperature setting, automatic start/stop, and fault warning functions;

Compatible with external control signal inputs for interlocked control with host equipment.

Environmental Adaptability

Cabinets with anti-corrosion coatings and sealed designs adapt to high-temperature, high-humidity, and high-dust industrial environments;

Wide voltage design (±20% voltage fluctuation tolerance) ensures stable operation in regions with unstable power grids.

Typical Application Scenarios

Machining Industry: CNC machine tool spindle cooling, continuous laser cutting equipment cooling;

Plastics Industry: Injection molding die temperature control, extruder forming process cooling;

Data Centers: Server cabinet cooling, UPS power supply temperature management;

Medical/Pharmaceutical: Freeze-drying equipment low-temperature process support, reactor temperature control;

Food Processing: Quick-freezing line temperature assurance, bakery equipment mold cooling.

Operational Advantages

Daily maintenance requires only checking heat sink cleanliness and ventilation, without professional water quality management;

Low-noise design (operating noise ≤65dB) suitable for installation near operating areas;

Long-life compressors and fluoride-free refrigerant design comply with environmental and sustainability requirements.

Designed with a “plug-and-play” philosophy, this series is ideal for industrial users lacking specialized maintenance teams or requiring rapid cooling system deployment, offering cost-effective basic industrial temperature control solutions.

Specifications

| Model Item | ICA-0.6 | ICA-1 | ICA-2 | ICA-3 | ICA-5 | ICA-6 | ICA-8 | ICA-10 | ||

| Performance parameter | ||||||||||

| Cooling capacity | kW | 1.6 | 2.7 | 5.2 | 9.1 | 15.0 | 18.0 | 23.0 | 29.5 | |

| 10³kcal/h | 1.4 | 2.3 | 4.5 | 7.8 | 12.9 | 15.5 | 19.8 | 25.4 | ||

| Power source | V/ph/Hz | 220/1/50 | 380/3/50 | |||||||

| Power input | kW | 0.9 | 1.2 | 2.2 | 2.9 | 5.3 | 6.5 | 8.4 | 10.5 | |

| Current | A | 4.6 | 5.9 | 11.3 | 8.2 | 11.7 | 12.2 | 20.0 | 23.4 | |

| Main component | ||||||||||

| Compressor | Type | Rotor type | Scroll type | |||||||

| Power | kW | 0.5 | 0.8 | 1.6 | 2.3 | 4.2 | 5.1 | 6.9 | 8.7 | |

|

Pump | Power | kW | 0.25 | 0.25 | 0.37 | 0.37 | 0.55 | 0.75 | 0.75 | 0.75 |

| Head | m | 36 | 34 | 26 | 24 | 28 | 33 | 30 | 27 | |

| Flow | m³/h | 0.28 | 0.46 | 0.89 | 1.6 | 2.6 | 3.1 | 4.0 | 5.1 | |

| L/min | 4.6 | 7.7 | 14.8 | 26.7 | 43.3 | 51.7 | 66.0 | 85.0 | ||

| Tank capacity | L | 12 | 20 | 35 | 60 | 70 | 70 | 100 | 135 | |

| Pipe size/Noise/Weight/Dimension | ||||||||||

| Pipe size | DN | 15 | 20 | 25 | 40 | |||||

| Noise | dB(A) | 56 | 58 | 58 | 60 | 61 | 62 | 64 | 65 | |

| Weight | kg | 50 | 68 | 108 | 140 | 185 | 210 | 260 | 310 | |

| Dim. | L | mm | 420 | 500 | 600 | 680 | 750 | 750 | 1350 | 1510 |

| W | mm | 420 | 500 | 600 | 680 | 750 | 750 | 680 | 750 | |

| H | mm | 815 | 950 | 1160 | 1360 | 1480 | 1480 | 1360 | 1480 | |

| Model Item | ICA-12 | ICA-15 | ICA-20 | ICA-25 | ICA-30 | ICA-40 | ICA-50 | ICA-60 | ||

| Performance parameter | ||||||||||

| Cooling capacity | kW | 35 | 44 | 58.5 | 69.0 | 86.0 | 116.0 | 140.0 | 168.0 | |

| 10³kcal/h | 30.1 | 37.8 | 50.3 | 59.3 | 74.1 | 100.0 | 120.0 | 145.0 | ||

| Power source | V/ph/Hz | 380/3/50 | ||||||||

| Power input | kW | 12.5 | 15.0 | 21.1 | 24.0 | 30.0 | 41.3 | 48.0 | 58.5 | |

| Current | A | 24.0 | 27.7 | 41.7 | 46.7 | 57.0 | 76.0 | 88.0 | 110.0 | |

| Main component | ||||||||||

| Compressor | type | Scroll type | ||||||||

| Power | kW | 10.1 | 12.5 | 17.4 | 20.2 | 25.0 | 34.8 | 40.6 | 50.0 | |

|

Pump | Power | kW | 1.2 | 1.2 | 2.2 | 2.2 | 2.2 | 3.5 | 3.5 | 4.0 |

| Head | m | 29 | 27 | 27 | 26 | 25 | 34 | 29 | 25 | |

| Flow | m³/h | 6.0 | 7.6 | 10.0 | 11.8 | 14.8 | 20.0 | 24.0 | 28.9 | |

| L/min | 100 | 127 | 167 | 197 | 247 | 333 | 400 | 480 | ||

| Tank capacity | L | 135 | 155 | 230 | 230 | 230 | 300 | 300 | 300 | |

| Pipe size/Noise/Weight/Dimension | ||||||||||

| Pipe size | DN | 40 | 50 | 65 | ||||||

| Noise | dB(A) | 65 | 66 | 67 | 68 | 68 | 69 | 69 | 69 | |

| Weight | kg | 340 | 415 | 620 | 670 | 780 | 1100 | 1300 | 1500 | |

| Dim. | L | mm | 1510 | 1785 | 2080 | 2080 | 2080 | 2200 | 3000 | 3400 |

| W | mm | 750 | 915 | 1050 | 1050 | 1050 | 1200 | 1200 | 1200 | |

| H | mm | 1480 | 1630 | 1820 | 1820 | 1910 | 2135 | 2120 | 2135 | |

*With the technological progress,we will periodically update products.Please follow KANSA website.

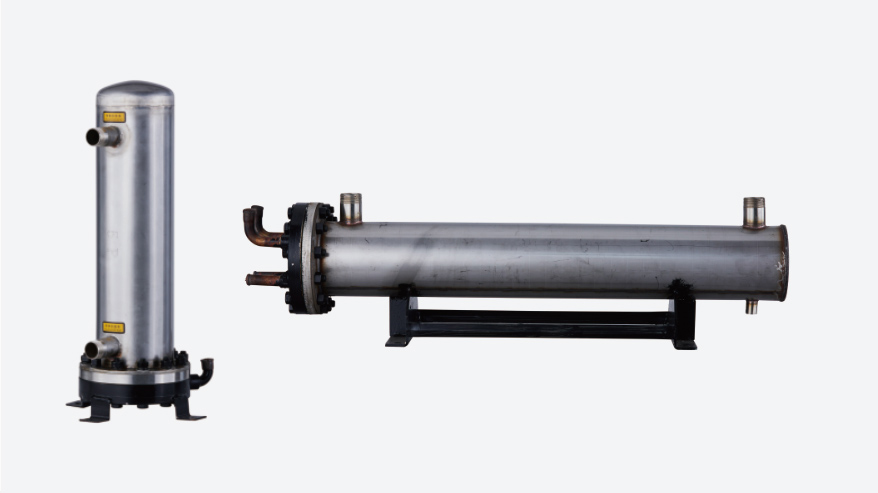

Stainless steel shell and tube evaporator

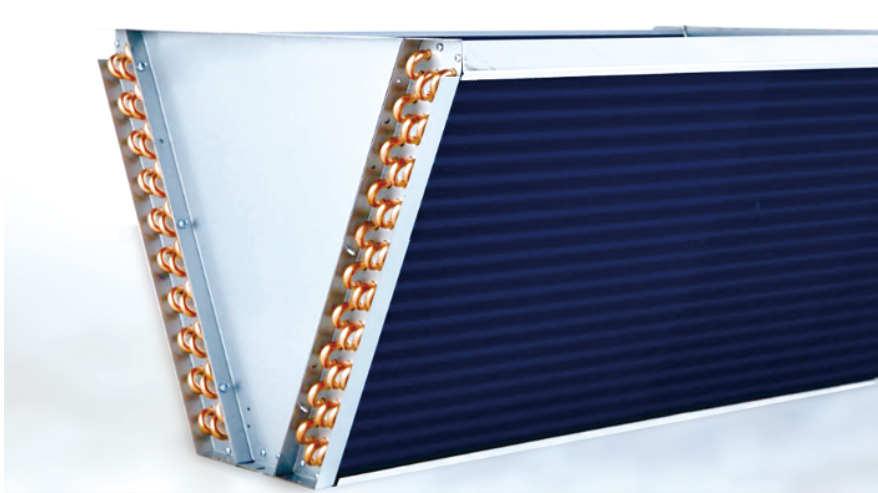

Stainless steel shell and tube evaporator I nnovative V-shaped fin condenser

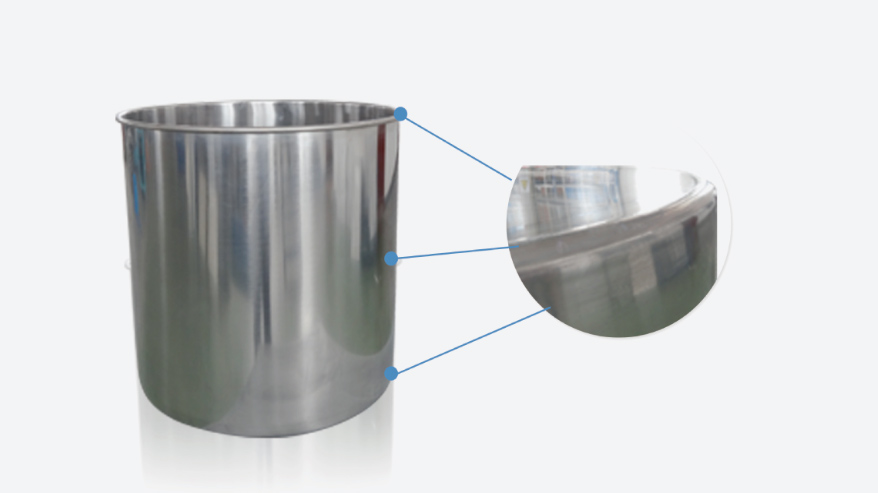

I nnovative V-shaped fin condenser Innovative new cylindrical water tank

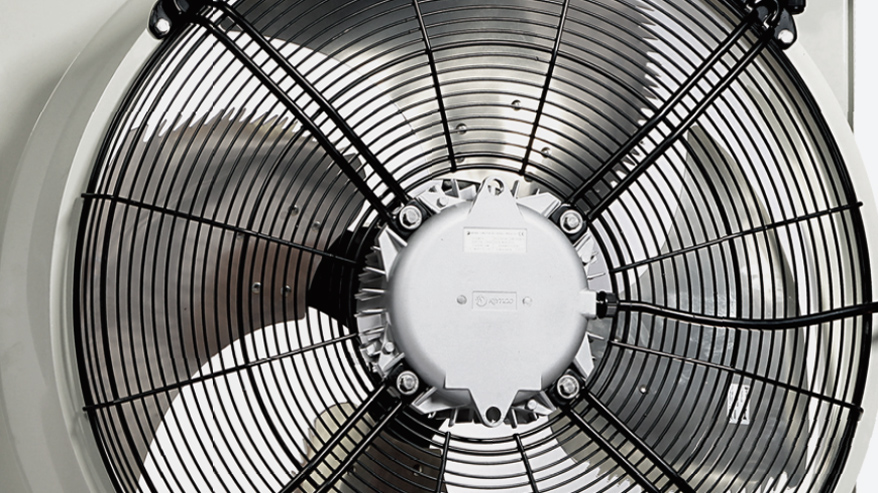

Innovative new cylindrical water tank High efficiency and low noise fan

High efficiency and low noise fan Intelligent touch screen controller

Intelligent touch screen controller High precision controller

High precision controller

Copper tube with internal thread

Copper tube with internal thread Sinusoidal heat transfer fins

Sinusoidal heat transfer fins Electric expansion PID technology

Electric expansion PID technology Innovative refrigerant distribution technology

Innovative refrigerant distribution technology Professional air flow channel design

Professional air flow channel design Air volume automatic control

Air volume automatic control

Over temperature protection

Over temperature protection Current protection

Current protection Self-diagnosis

Self-diagnosis Intelligent antifreeze

Intelligent antifreeze Water flow alarm

Water flow alarm Water level alarm

Water level alarm Pressure alarm

Pressure alarm Timing switch on and off

Timing switch on and off

Famous brand compressor

Famous brand compressor Imported brand accessories

Imported brand accessories Keep improving everywhere

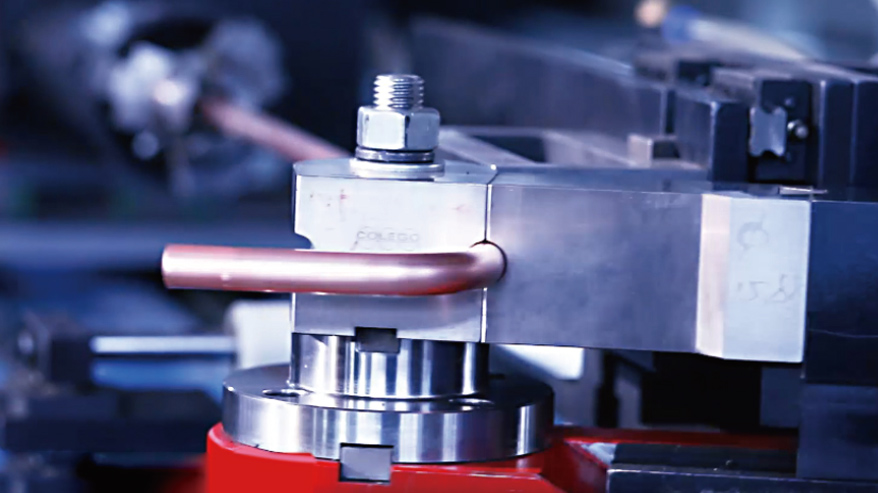

Keep improving everywhere 3D pipe bending machine

3D pipe bending machine Automatic refrigerant adding machine

Automatic refrigerant adding machine Automatic welding machine

Automatic welding machine

Sheet metal precision drawing

Sheet metal precision drawing Drawing forming guide ring

Drawing forming guide ring Robot bending machine

Robot bending machine Laser welding

Laser welding Automatic cutting machine

Automatic cutting machine Automatic joint welding

Automatic joint welding