Description

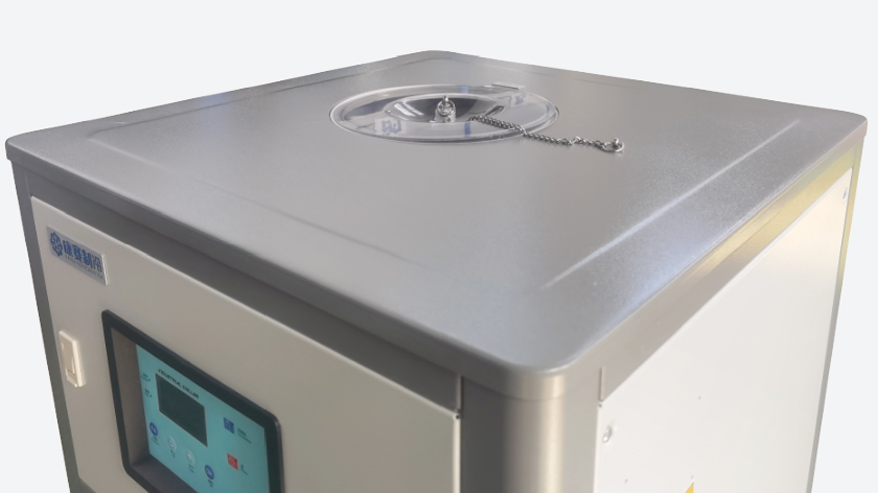

ICA-8 Air-Cooled Industrial Chiller

Working Principle

This chiller operates on a vapor-compression refrigeration cycle, integrating a compressor, evaporator, air-cooled condenser, and thermal expansion valve. Liquid refrigerant absorbs heat from the cooling medium in the evaporator and vaporizes, then the compressor transforms it into high-temperature, high-pressure gas. The gas is condensed into liquid in the air-cooled condenser via forced ventilation, and returns to the evaporator after pressure reduction through the expansion valve, forming a continuous cooling cycle.

Key Features

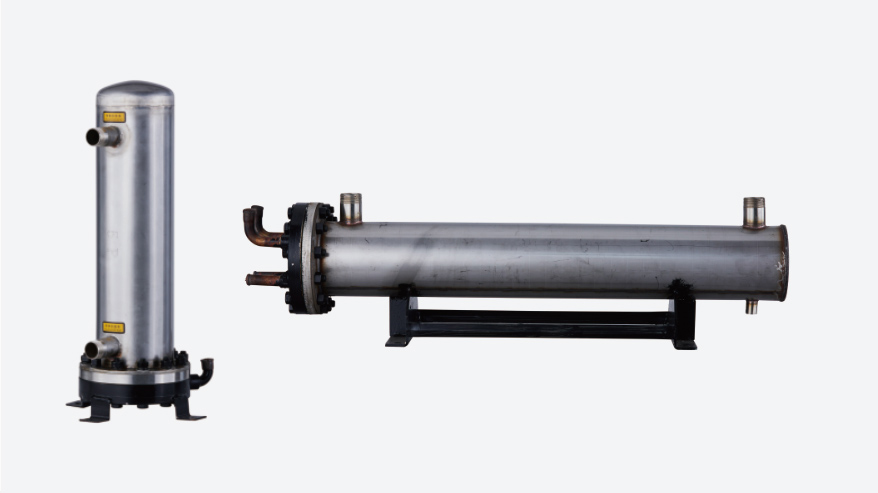

1.High Efficiency & Stability:Equipped with a scroll compressor from international brands and high-efficiency shell-and-tube heat exchangers, delivering 8HP (approx. 23kW) cooling capacity for medium and large-scale industrial cooling needs.

2.Intelligent Control:Microcomputer control system enables precise temperature adjustment (5°C-35°C), with user-friendly interfaces and multi-unit synchronization capabilities.

Environmental Adaptability:No cooling towers or water circuits required. The air-cooled design suits water-scarce regions or mobile applications, supporting single/multi-unit installations.

3.Safety & Reliability:Comprehensive safety modules including phase failure protection, overload protection, and high/low pressure safeguards. Stainless steel tanks and anti-corrosion finned condensers enhance durability.

4.Quiet & Energy-Saving:Low-noise fans and energy-efficient compressors ensure operation below 65dB(A), compliant with industrial environmental standards.

Typical Applications

Suitable for plastic molding, chemical reactor temperature control, pharmaceutical cold storage, mold cooling, food freezing, electroplating solution temperature regulation, and other scenarios requiring equipment mobility.

Specifications

| Model Item | ICA-0.6 | ICA-1 | ICA-2 | ICA-3 | ICA-5 | ICA-6 | ICA-8 | ICA-10 | ||

| Performance parameter | ||||||||||

| Cooling capacity | kW | 1.6 | 2.7 | 5.2 | 9.1 | 15.0 | 18.0 | 23.0 | 29.5 | |

| 10³kcal/h | 1.4 | 2.3 | 4.5 | 7.8 | 12.9 | 15.5 | 19.8 | 25.4 | ||

| Power source | V/ph/Hz | 220/1/50 | 380/3/50 | |||||||

| Power input | kW | 0.9 | 1.2 | 2.2 | 2.9 | 5.3 | 6.5 | 8.4 | 10.5 | |

| Current | A | 4.6 | 5.9 | 11.3 | 8.2 | 11.7 | 12.2 | 20.0 | 23.4 | |

| Main component | ||||||||||

| Compressor | Type | Rotor type | Scroll type | |||||||

| Power | kW | 0.5 | 0.8 | 1.6 | 2.3 | 4.2 | 5.1 | 6.9 | 8.7 | |

|

Pump | Power | kW | 0.25 | 0.25 | 0.37 | 0.37 | 0.55 | 0.75 | 0.75 | 0.75 |

| Head | m | 36 | 34 | 26 | 24 | 28 | 33 | 30 | 27 | |

| Flow | m³/h | 0.28 | 0.46 | 0.89 | 1.6 | 2.6 | 3.1 | 4.0 | 5.1 | |

| L/min | 4.6 | 7.7 | 14.8 | 26.7 | 43.3 | 51.7 | 66.0 | 85.0 | ||

| Tank capacity | L | 12 | 20 | 35 | 60 | 70 | 70 | 100 | 135 | |

| Pipe size/Noise/Weight/Dimension | ||||||||||

| Pipe size | DN | 15 | 20 | 25 | 40 | |||||

| Noise | dB(A) | 56 | 58 | 58 | 60 | 61 | 62 | 64 | 65 | |

| Weight | kg | 50 | 68 | 108 | 140 | 185 | 210 | 260 | 310 | |

| Dim. | L | mm | 420 | 500 | 600 | 680 | 750 | 750 | 1350 | 1510 |

| W | mm | 420 | 500 | 600 | 680 | 750 | 750 | 680 | 750 | |

| H | mm | 815 | 950 | 1160 | 1360 | 1480 | 1480 | 1360 | 1480 | |

| Model Item | ICA-12 | ICA-15 | ICA-20 | ICA-25 | ICA-30 | ICA-40 | ICA-50 | ICA-60 | ||

| Performance parameter | ||||||||||

| Cooling capacity | kW | 35 | 44 | 58.5 | 69.0 | 86.0 | 116.0 | 140.0 | 168.0 | |

| 10³kcal/h | 30.1 | 37.8 | 50.3 | 59.3 | 74.1 | 100.0 | 120.0 | 145.0 | ||

| Power source | V/ph/Hz | 380/3/50 | ||||||||

| Power input | kW | 12.5 | 15.0 | 21.1 | 24.0 | 30.0 | 41.3 | 48.0 | 58.5 | |

| Current | A | 24.0 | 27.7 | 41.7 | 46.7 | 57.0 | 76.0 | 88.0 | 110.0 | |

| Main component | ||||||||||

| Compressor | type | Scroll type | ||||||||

| Power | kW | 10.1 | 12.5 | 17.4 | 20.2 | 25.0 | 34.8 | 40.6 | 50.0 | |

|

Pump | Power | kW | 1.2 | 1.2 | 2.2 | 2.2 | 2.2 | 3.5 | 3.5 | 4.0 |

| Head | m | 29 | 27 | 27 | 26 | 25 | 34 | 29 | 25 | |

| Flow | m³/h | 6.0 | 7.6 | 10.0 | 11.8 | 14.8 | 20.0 | 24.0 | 28.9 | |

| L/min | 100 | 127 | 167 | 197 | 247 | 333 | 400 | 480 | ||

| Tank capacity | L | 135 | 155 | 230 | 230 | 230 | 300 | 300 | 300 | |

| Pipe size/Noise/Weight/Dimension | ||||||||||

| Pipe size | DN | 40 | 50 | 65 | ||||||

| Noise | dB(A) | 65 | 66 | 67 | 68 | 68 | 69 | 69 | 69 | |

| Weight | kg | 340 | 415 | 620 | 670 | 780 | 1100 | 1300 | 1500 | |

| Dim. | L | mm | 1510 | 1785 | 2080 | 2080 | 2080 | 2200 | 3000 | 3400 |

| W | mm | 750 | 915 | 1050 | 1050 | 1050 | 1200 | 1200 | 1200 | |

| H | mm | 1480 | 1630 | 1820 | 1820 | 1910 | 2135 | 2120 | 2135 | |

*With the technological progress,we will periodically update products.Please follow KANSA website.

Stainless steel shell and tube evaporator

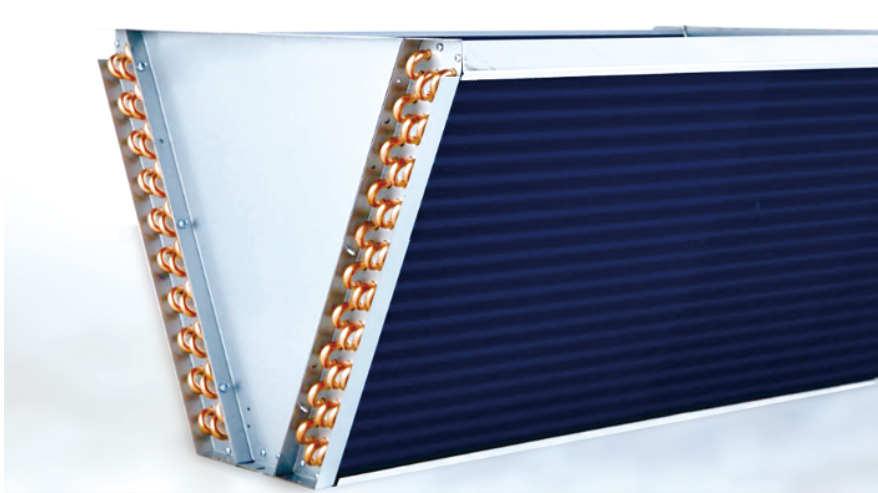

Stainless steel shell and tube evaporator I nnovative V-shaped fin condenser

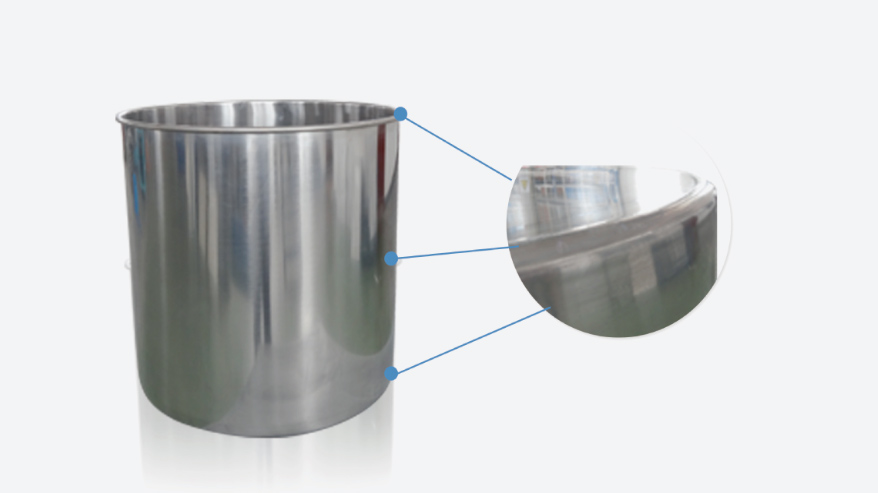

I nnovative V-shaped fin condenser Innovative new cylindrical water tank

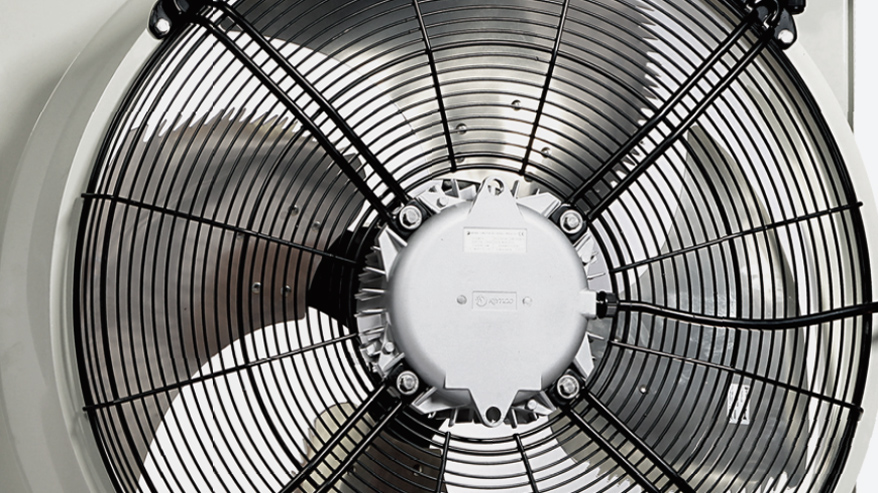

Innovative new cylindrical water tank High efficiency and low noise fan

High efficiency and low noise fan Intelligent touch screen controller

Intelligent touch screen controller High precision controller

High precision controller

Copper tube with internal thread

Copper tube with internal thread Sinusoidal heat transfer fins

Sinusoidal heat transfer fins Electric expansion PID technology

Electric expansion PID technology Innovative refrigerant distribution technology

Innovative refrigerant distribution technology Professional air flow channel design

Professional air flow channel design Air volume automatic control

Air volume automatic control

Over temperature protection

Over temperature protection Current protection

Current protection Self-diagnosis

Self-diagnosis Intelligent antifreeze

Intelligent antifreeze Water flow alarm

Water flow alarm Water level alarm

Water level alarm Pressure alarm

Pressure alarm Timing switch on and off

Timing switch on and off

Famous brand compressor

Famous brand compressor Imported brand accessories

Imported brand accessories Keep improving everywhere

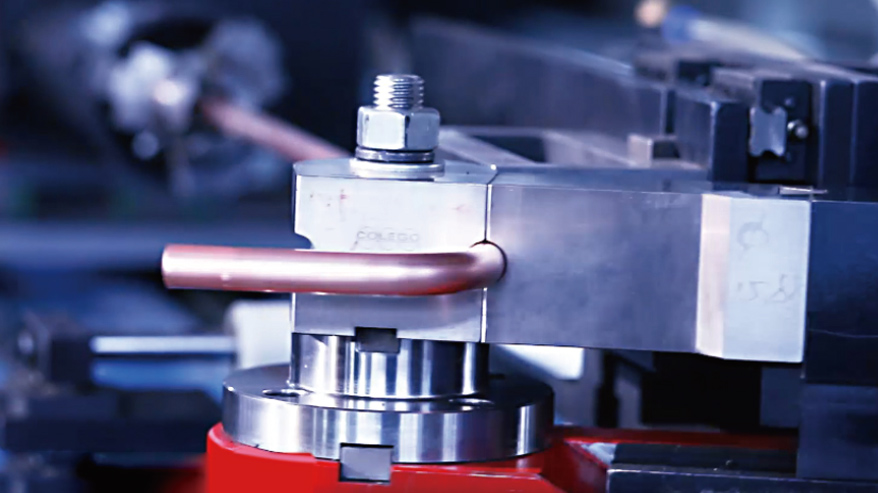

Keep improving everywhere 3D pipe bending machine

3D pipe bending machine Automatic refrigerant adding machine

Automatic refrigerant adding machine Automatic welding machine

Automatic welding machine

Sheet metal precision drawing

Sheet metal precision drawing Drawing forming guide ring

Drawing forming guide ring Robot bending machine

Robot bending machine Laser welding

Laser welding Automatic cutting machine

Automatic cutting machine Automatic joint welding

Automatic joint welding