Analysis of air-cooled chillers used in the injection molding industry

Professional application in plastics and injection molding industry

1. Injection molding temperature control

During the injection molding production process, precise control of mold temperature directly affects product quality and production efficiency. Kangsi air-cooled chillers provide a full range of cooling solutions for the injection molding industry:

1.1 Small precision injection molding

Applicable to the production of precision plastic parts such as electronic connectors and medical devices, requiring:

Quick response to mold temperature changes

Eliminate product deformation caused by uneven cooling

Maintain temperature stability within ±0.5℃

1.2 Injection molding of large thick-walled products

Characteristics of thick-walled products such as automotive parts and home appliance housings:

Provide large-flow cooling water circulation (up to 120m³/h)

Secondary cooling system prevents water temperature from rising

High-pressure design ensures that cooling water flows fully through complex mold waterways

1.3 High-speed thin-wall injection molding

Meet the high-speed production needs of packaging containers, disposable tableware, etc.:

Ultra-fast cooling capacity shortens molding cycle

Multi-pump parallel design ensures continuous and stable cooling

Specially designed buffer water tank reduces pressure fluctuations

2. Extrusion molding production line

Provides for the extrusion production of plastic pipes, plates, profiles, etc.:

Partitioned cooling control of screws and barrels

Reliability of long-term continuous operation

Adapt to the cooling needs of different plastic raw materials (PP, PE, PVC, etc.)

3. Blow molding applications

In the blow molding production of PET bottles, plastic containers, etc.:

Precisely control the temperature distribution of the parison

Rapid cooling ensures the transparency of the bottle wall

Energy-saving design reduces production costs

4. Special plastic processing technology

Reaction injection molding (RIM): Control the reaction temperature to prevent premature solidification

Gas-assisted injection molding: Precisely control the cooling of the gas channel

Multi-component injection molding: Independently control the cooling rate of different materials

Case Study: For a major automotive components wholesaler, we implemented a customized solution featuring 20×80HP air-cooled units with advanced predictive maintenance capabilities. The system achieved uninterrupted 365-day continuous operation with less than 0.5% downtime, while reducing energy consumption by 28% compared to their previous installation.

Core Technical Advantages of Air-Cooled Chillers

As a professional industrial temperature control equipment manufacturer with over two decades of industry experience, KANSA Refrigeration has pioneered the development of advanced air-cooled chiller systems that set new benchmarks in energy efficiency and operational reliability. Our self-developed air-cooled chillers incorporate cutting-edge heat exchange technologies and innovative system architectures that deliver 30% more compact installation footprints compared to conventional water-cooled models, while completely eliminating the need for additional cooling towers and complex piping infrastructures.

Our state-of-the-art factory complex spans over 8,000 square meters in Shanghai province, featuring fully automated sheet metal processing lines with 0.1mm precision tolerances, robotic welding stations, and comprehensive intelligent testing equipment. Every chiller unit undergoes rigorous quality control procedures to ensure full compliance with ISO9001 quality management system certification, as well as meeting stringent international standards including CE, UL, and ASHRAE performance requirements.

Advanced Product Features:

- Superior Energy Efficiency:Utilizing our proprietary hybrid scroll/screw compressor technology paired with high-efficiency EC fan arrays, our chillers achieve industry-leading IPLV (Integrated Part Load Value) ratings exceeding 4.5, delivering substantial energy savings throughout the entire operating range.

- Intelligent Control Ecosystem:The 7-inch full-color touchscreen HMI integrates advanced IoT connectivity modules, enabling real-time remote monitoring, predictive maintenance alerts, and seamless integration with building management systems through Modbus, BACnet, and LonWorks protocols.

- Exceptional Operational Stability:Engineered for reliable performance across extreme ambient conditions (-15℃ to 45℃), our chillers incorporate multiple redundant protection systems including high/low pressure safeguards, phase sequence monitoring, and anti-freeze protection circuits.

- Modular Scalability:With single unit capacities ranging from 5-200RT, our modular design philosophy allows for flexible multi-unit parallel configurations to meet custom capacity requirements, featuring intelligent load balancing algorithms that optimize energy consumption.

- Environmentally Conscious Design:Available with R410A, R32, or future-proof R290 natural refrigerant options, our chillers achieve remarkably low noise levels down to 65dB(A) through advanced acoustic engineering and vibration isolation technologies.

KANSA Refrigeration’s Comprehensive Competitive Advantages

As an industry-leading manufacturer with 25 years of continuous innovation, we have developed three interconnected advantage systems that differentiate our solutions in global markets:

1. Cutting-Edge Research and Development Capabilities

Our 5,000 square meter R&D center houses advanced testing facilities including:

Full-scale enthalpy difference laboratories with climate simulation capabilities

Computational Fluid Dynamics (CFD) simulation workstations

Materials testing laboratory for corrosion resistance evaluation

Acoustic measurement chambers for noise optimization

In partnership with Tsinghua University’s Department of Thermal Engineering, we maintain a joint research center focused on next-generation heat transfer technologies. Our annual R&D investment exceeds 8% of revenue, resulting in 67 patented technologies including 12 invention patents in advanced refrigeration cycles and heat exchanger designs.

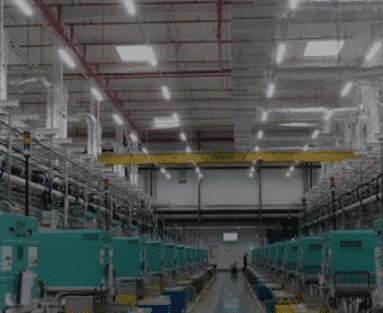

2. World-Class Manufacturing Infrastructure

Our vertically integrated production facilities feature:

Industry 4.0 automated production lines with real-time quality monitoring

Robotic welding cells achieving 0.1mm repeatability

Fully automated refrigerant charging and testing stations

40-ton overhead cranes for large system assembly

On-site metal fabrication including laser cutting and CNC bending

The manufacturing execution system (MES) tracks every component through the entire production process, ensuring complete traceability. Our flexible production system accommodates everything from single custom units to large wholesale orders with lead times 30% shorter than industry averages.

3. Global Service and Support Network

Our customer-focused service infrastructure includes:

Regional technical support centers in Asia, Europe, and North America

24/7 multilingual technical assistance hotlines

Augmented reality (AR) remote support capabilities

Localized spare parts inventories at 5 global logistics hubs

Certified technician training programs at our headquarters

The proactive monitoring platform analyzes operational data from connected chillers worldwide, identifying potential issues before they affect performance. Our average emergency response time is under 24 hours for critical applications.

Customer Value Creation Process

Our systematic approach ensures optimal solutions for every application:

1. Comprehensive Needs Assessment

On-site thermal load evaluation using infrared thermography

Process cooling requirement analysis

Utility infrastructure review

Future expansion planning

2. Engineered Solution Development

CFD modeling for system optimization

Energy efficiency simulations

Control strategy development

3D plant layout integration

3. Precision Manufacturing

Custom fabrication to exact specifications

Rigorous component testing

Complete factory acceptance testing

Detailed documentation packages

4. Professional Installation & Commissioning

Certified installation teams

Full system performance validation

Operator training programs

Initial maintenance planning

5. Continuous Performance Optimization

Remote monitoring services

Periodic efficiency audits

Preventive maintenance programs

Technology upgrade options

Complete Product Portfolio

Standard Series Solutions

Compact Units (5-20HP): Ideal for small-scale processes (-5℃~30℃ range)

Mid-Range Systems (25-100HP): Workhorse models for most industrial applications (-15℃~35℃)

Large Capacity Units (120-200HP): High-efficiency solutions for major facilities (-25℃~45℃)

Special Application Series

Ultra-Low Temperature: Cascade systems down to -40℃ for specialty processes

Hazardous Area Certified: Complete ATEX-compliant explosion-proof range

Variable Frequency Drive: IP65-rated outdoor models with wide turndown ratios

Reversible Heat Pumps: Simultaneous heating/cooling capability for energy recovery

Environmental Stewardship Commitments

- Sustainable Manufacturing

92% material recycling rate across all production processes

Solar panel arrays providing 30% of factory power needs

Zero landfill waste policy

- Eco-Conscious Products

Full transition to R290 natural refrigerant by 2025

Energy recovery options for waste heat utilization

Lead-free construction materials

- Circular Economy Initiatives

Chiller refurbishment and modernization programs

Core component reuse system

End-of-life equipment recycling services

- Carbon Footprint Reduction

Logistics optimization reducing transportation emissions

Energy efficiency consulting services

Carbon offset partnership programs

Why Choose KANSA as Your Cooling Solutions Provider?

Shanghai KANSA Refrigeration Equipment Co., Ltd. is an innovator in the industry, with strong R&D capabilities, advanced equipment, and professional products and solutions. Over the years, Kangsai has met customer needs with its unremitting pursuit of industry-leading technology and its ability to foresee industry trends, while maintaining the Kangsai brand’s characteristics of sincerity, rigor, and high quality. Our company uses advanced production and inspection equipment, and implements strict control over every detail from raw materials to finished products to ensure the performance and quality of each product.

Manufacturer Direct Pricing: As a factory-direct supplier, we offer competitive wholesale rates without middleman markups

Application Expertise: Our engineers understand your industry’s unique cooling challenges

Rapid Prototyping: Ability to develop and test custom configurations quickly

Scalable Production: From small batches to large volume orders

Comprehensive Support: From initial consultation through installation and maintenance

For OEM partners and system integrators, KANSA offers white-label custom solutions with flexible branding options. Our engineering team can collaborate on fully integrated thermal management systems tailored to your specific equipment requirements.

KANSA Refrigeration Company Strength Display

Company Profile

Shanghai Kangsai Refrigeration Equipment Co., Ltd. was established in 2002. It is a national high-tech enterprise specializing in the research and development, production and sales of industrial refrigeration equipment. As a leading manufacturer and supplier in the industry, we have two modern production bases:

Two major production bases in Shanghai and Shenzhen

- Shanghai Factory

The Shanghai Factory is located in Pudong New Area, Shanghai. It has a modern factory building of 8,000 square meters and related supporting facilities. The company has a large number of experienced and well-trained managers and technical workers, as well as experienced technical experts. In terms of manufacturing equipment and product testing and detection methods, they include: fully automatic sheet metal flexible production line, AMADA digital bending machine, fully automatic loading and unloading laser cutting machine, a full set of fin heat exchanger production line, high vacuum cold well degreasing furnace, fully automatic water storage tank production line, fully automatic fluorine pipeline production line, product online testing platform and electrical safety performance device certified by national authoritative departments, etc., and follow Kangsai’s quality control system to achieve high-quality goals and manufacture high-quality products.

- Shenzhen Factory

The Shenzhen Factory is located in Bao’an District, Shenzhen, with a factory area of 4,800 square meters and a beautiful office environment. All technology and production management are synchronized with Shanghai Kangsai. The company has advanced sheet metal production lines, AMADA digital bending machines, high-speed laser cutting machines, and a full set of fin production lines. Fully automatic fluorine pipeline production equipment.

Global Applications and Case Studies

KANSA precision chillers have been successfully deployed in:

University research laboratories conducting nanotechnology studies

Semiconductor fabrication facilities producing advanced chips

Aerospace component manufacturers requiring micron-level machining accuracy

Medical device companies developing next-generation imaging systems

National research institutions with demanding experimental requirements

Our portfolio includes compact 1kW chillers for benchtop instruments up to 500kW centralized cooling systems for industrial processes. All systems share the same commitment to precision, reliability, and energy efficiency.

Partner with KANSA for Your Cooling Needs

As a fully integrated manufacturer, KANSA Refrigeration offers the industry’s most comprehensive range of temperature control solutions from compact 3.5kW chillers to 2000kW centralized systems. Our expertise covers:

OEM and Private Label Services: Complete white-label solutions with your branding

Application-Specific Custom Designs: Engineering support for unique requirements

Volume Wholesale Programs: Attractive pricing for large orders and multi-site deployments

Turnkey Project Solutions: Single-source responsibility for complete cooling systems

Contact KANSA for Your Custom Cooling Solution

As a professional manufacturer with strong factory capabilities, KANSA Refrigeration stands ready to provide the perfect temperature control solution for your application. Whether you need standard models from our catalog or fully custom-designed systems, our team will deliver optimal performance and reliability.

We welcome wholesale inquiries and long-term partnership opportunities. Our global distribution network ensures prompt delivery and local support wherever your operations are located.

Discover the KANSA difference in precision cooling technology. Contact our technical sales team today to discuss your requirements and receive a tailored proposal for your specific application needs.