Application of Cooling Equipment Units in the Laser Industry

Background of Application

In the laser industry, cooling equipment units play a crucial role. Laser devices generate a significant amount of heat during operation, and if not dissipated promptly and effectively, it can lead to performance degradation or even damage. Cooling equipment units ensure that lasers and other critical components remain within an optimal temperature range by circulating coolant, thereby enhancing equipment stability and lifespan.

Key Application Scenarios:

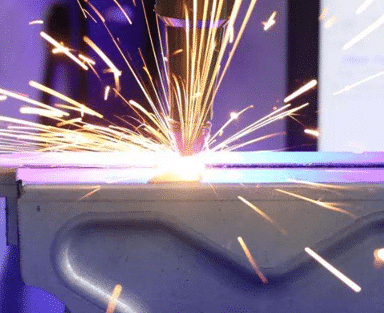

- Laser Cutting Machines: High-power laser cutting machines generate substantial heat when cutting metal materials. Cooling equipment units effectively reduce the temperature of laser generators and optical components, ensuring cutting precision and efficiency.

- Laser Marking Machines: During prolonged continuous operation, the laser source and galvanometer system of laser marking machines require stable cooling to prevent performance degradation caused by overheating.

- Laser Welding Machines: The laser source produces high temperatures during welding. Cooling equipment units rapidly dissipate heat, ensuring welding quality and equipment longevity.

- Laser Medical Devices: Such as laser beauty devices and laser surgical equipment, cooling systems ensure safe operation at appropriate temperatures, preventing harm to patients and operators.

Key Advantages :

1.Efficient Heat Dissipation: Rapid heat removal through water or air cooling technology.

2.High Stability: Maintains laser equipment at a constant temperature, reducing failure rates.

3.Energy Efficiency and Environmental Friendliness: Optimized cooling system design reduces energy consumption and minimizes environmental impact.