Application of cooling equipment units in the printing industry

In the printing industry, cooling equipment units are key components to ensure production efficiency and equipment stability. Printing equipment generates a lot of heat during high-speed operation, especially when ink is drying, paper is transported, and electronic components are working. If the heat cannot be dissipated in time, it may lead to a decline in printing quality (such as ink smearing, paper deformation), an increase in equipment failure rate, and even shorten the life of the equipment. The cooling equipment unit ensures that the printing process runs within the ideal temperature range through precise temperature control.

Main application scenarios

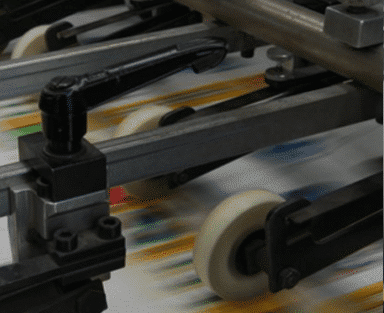

1. Offset Printing Machines

The rollers and ink systems of offset printing machines accumulate high temperatures during continuous operation. The cooling equipment uses water cooling or air cooling technology to reduce the temperature of key components to avoid excessive drying of ink or deformation of paper due to heat.

2. Digital Printers

High-speed inkjet print heads and electronic control modules require stable cooling to prevent print head clogging or circuit overheating, thereby ensuring color consistency and printing accuracy.

3. UV Curing Systems

UV curing lamps generate high-intensity heat during post-printing processing. Cooling equipment can quickly reduce the temperature of the lamp tube and peripheral equipment, extend the life of the lamp tube and prevent the printing material (such as plastic, film) from being damaged by heat.

4. Post-printing processing equipment (such as laminating machine, hot stamping machine)

During the laminating or hot stamping process, the heating roller and pressure device need to cooperate with the cooling system to achieve temperature balance to prevent the material from sticking or deforming.

Advantages of cooling equipment units

1. Improve printing quality: Accurate temperature control reduces ink diffusion and paper shrinkage, ensuring pattern clarity and dimensional stability

2. Extend equipment life: Prevent electronic components and mechanical parts from aging due to high temperature.

3. Energy saving and consumption reduction: The intelligent temperature control system adjusts the cooling intensity as needed to reduce energy waste.

4. Adapt to high-speed production: Support 24-hour continuous operation of printing equipment to avoid shutdown due to overheating.