Working principle, composition and fault analysis of chiller

2025-09-25

|

|

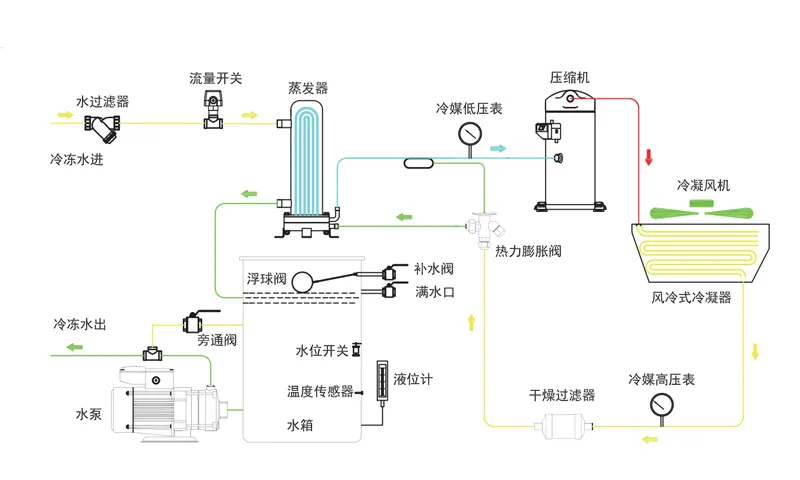

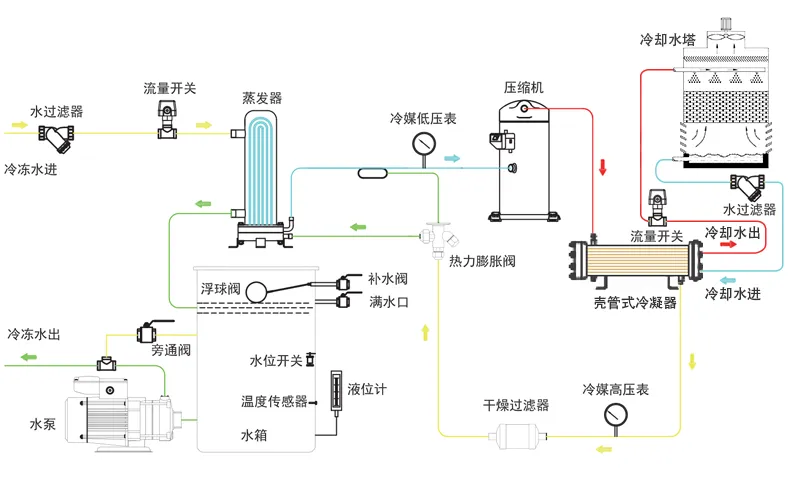

| Air-cooled refrigeration cycle | Water-cooled refrigeration cycle |

A chiller consists of three interconnected systems: the refrigerant circulation system, the water circulation system, and the electrical automatic control system.

1. Refrigerant Circulation System:

The liquid refrigerant in the evaporator absorbs heat from the water and begins to evaporate. The liquid refrigerant completely evaporates and becomes a gas, which is then drawn into the compressor and compressed. The gaseous refrigerant absorbs heat in the condenser and condenses into a liquid. After throttling through a thermal expansion valve (or capillary tube), it becomes low-temperature, low-pressure refrigerant and enters the evaporator, completing the refrigerant cycle.

2. Basic Components of the Refrigeration System:

Compressor: The compressor is the core component of the refrigeration system, converting input electrical energy into mechanical energy to compress the refrigerant.

Condenser: During the refrigeration process, the condenser outputs heat energy and condenses the refrigerant. The high-pressure, superheated vapor discharged from the refrigeration compressor enters the condenser, where it transfers the heat absorbed in the evaporator, refrigeration compressor, and piping to the surrounding medium (water or air). The high-pressure, superheated refrigerant vapor then condenses back into a liquid.

Liquid Receiver: The liquid receiver is installed after the condenser and is directly connected to the condenser's drain pipe. Refrigerant from the condenser should flow unimpeded into the receiver, fully utilizing the condenser's cooling area. Furthermore, as the heat load on the evaporator changes, the refrigerant demand also fluctuates. In these situations, the liquid receiver serves to regulate and store refrigerant.

Filter Drier: The refrigeration cycle must be protected from the ingress of moisture and contaminants (oil, iron, and copper shavings). If moisture in the system is not completely removed, the refrigerant may freeze into ice due to the drop in pressure and temperature as it passes through the throttle valve (thermal expansion valve or capillary tube), blocking the passage and affecting the proper operation of the refrigeration unit.

Thermal Expansion Valve: The thermal expansion valve serves as both a flow control valve and a throttle valve in the refrigeration system. It is installed between the filter drier and the evaporator in the refrigeration unit, and its temperature sensor is wrapped around the evaporator outlet. Its primary function is to throttle and reduce the pressure of high-pressure, room-temperature refrigerant liquid as it flows through the thermal expansion valve, transforming it into low-temperature, low-pressure refrigerant vapor. This vaporizes and absorbs heat within the evaporator, achieving the desired cooling effect.

Evaporator: An evaporator is a heat exchange device that absorbs heat from the medium being cooled by evaporating refrigerant liquid. Its function in a refrigeration system is to absorb heat (or output cooling capacity). To ensure a stable and sustained evaporation process, the evaporating gas must be continuously extracted by a refrigeration compressor to maintain a certain evaporation pressure.

Refrigerant: NTC uses R22 As a refrigerant, it carries heat and absorbs and releases heat as its state changes.

3. Water Circulation System:

The water circulation system uses a water pump to pump water from the water tank to the equipment to be cooled. The chilled water removes heat, raising its temperature before returning to the chilled water tank.

4. Electrical Automatic Control System:

The electrical automatic control system consists of a power supply and an automatic control section.

The power supply supplies power to the compressor, fan, water pump, and other components through a contactor.

The automatic control section includes a thermostat, pressure protection, timer, relay, overload protection, and other components, which combine to automatically start and stop the system based on water temperature, as well as provide protection.

|

|

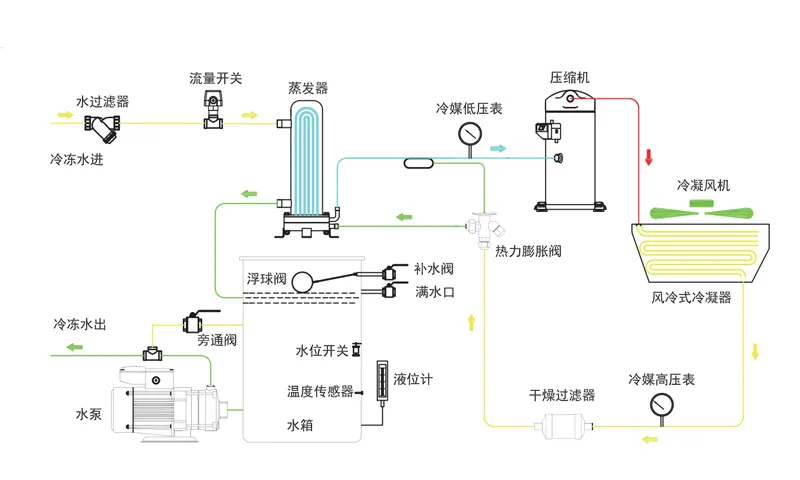

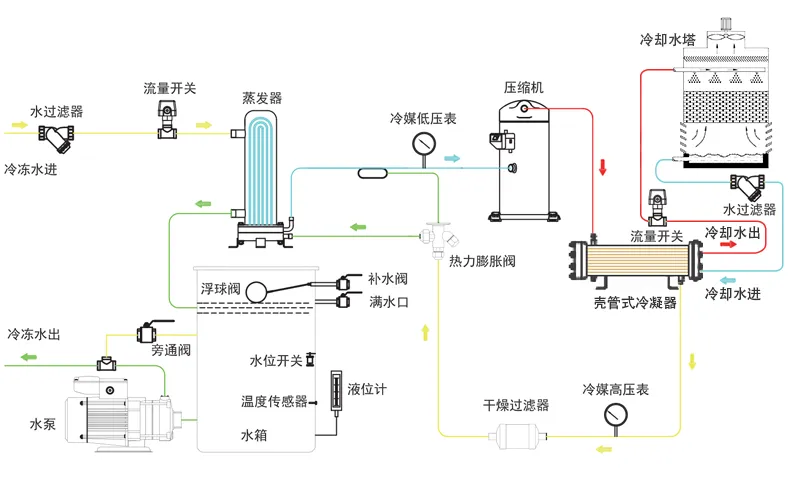

| Air-cooled refrigeration cycle | Water-cooled refrigeration cycle |

A chiller consists of three interconnected systems: the refrigerant circulation system, the water circulation system, and the electrical automatic control system.

1. Refrigerant Circulation System:

The liquid refrigerant in the evaporator absorbs heat from the water and begins to evaporate. The liquid refrigerant completely evaporates and becomes a gas, which is then drawn into the compressor and compressed. The gaseous refrigerant absorbs heat in the condenser and condenses into a liquid. After throttling through a thermal expansion valve (or capillary tube), it becomes low-temperature, low-pressure refrigerant and enters the evaporator, completing the refrigerant cycle.

2. Basic Components of the Refrigeration System:

Compressor: The compressor is the core component of the refrigeration system, converting input electrical energy into mechanical energy to compress the refrigerant.

Condenser: During the refrigeration process, the condenser outputs heat energy and condenses the refrigerant. The high-pressure, superheated vapor discharged from the refrigeration compressor enters the condenser, where it transfers the heat absorbed in the evaporator, refrigeration compressor, and piping to the surrounding medium (water or air). The high-pressure, superheated refrigerant vapor then condenses back into a liquid.

Liquid Receiver: The liquid receiver is installed after the condenser and is directly connected to the condenser's drain pipe. Refrigerant from the condenser should flow unimpeded into the receiver, fully utilizing the condenser's cooling area. Furthermore, as the heat load on the evaporator changes, the refrigerant demand also fluctuates. In these situations, the liquid receiver serves to regulate and store refrigerant.

Filter Drier: The refrigeration cycle must be protected from the ingress of moisture and contaminants (oil, iron, and copper shavings). If moisture in the system is not completely removed, the refrigerant may freeze into ice due to the drop in pressure and temperature as it passes through the throttle valve (thermal expansion valve or capillary tube), blocking the passage and affecting the proper operation of the refrigeration unit.

Thermal Expansion Valve: The thermal expansion valve serves as both a flow control valve and a throttle valve in the refrigeration system. It is installed between the filter drier and the evaporator in the refrigeration unit, and its temperature sensor is wrapped around the evaporator outlet. Its primary function is to throttle and reduce the pressure of high-pressure, room-temperature refrigerant liquid as it flows through the thermal expansion valve, transforming it into low-temperature, low-pressure refrigerant vapor. This vaporizes and absorbs heat within the evaporator, achieving the desired cooling effect.

Evaporator: An evaporator is a heat exchange device that absorbs heat from the medium being cooled by evaporating refrigerant liquid. Its function in a refrigeration system is to absorb heat (or output cooling capacity). To ensure a stable and sustained evaporation process, the evaporating gas must be continuously extracted by a refrigeration compressor to maintain a certain evaporation pressure.

Refrigerant: NTC uses R22 As a refrigerant, it carries heat and absorbs and releases heat as its state changes.

3. Water Circulation System:

The water circulation system uses a water pump to pump water from the water tank to the equipment to be cooled. The chilled water removes heat, raising its temperature before returning to the chilled water tank.

4. Electrical Automatic Control System:

The electrical automatic control system consists of a power supply and an automatic control section.

The power supply supplies power to the compressor, fan, water pump, and other components through a contactor.

The automatic control section includes a thermostat, pressure protection, timer, relay, overload protection, and other components, which combine to automatically start and stop the system based on water temperature, as well as provide protection.

Previous: No more data