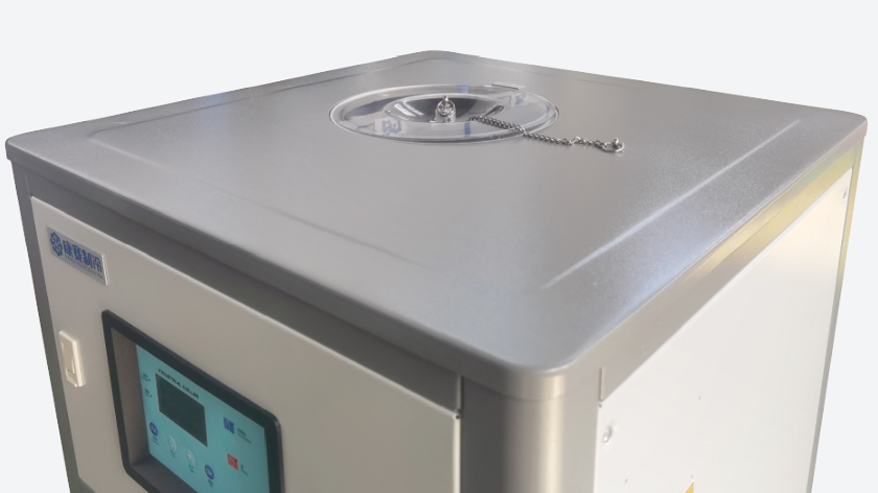

ICS-50A Air Cooled Scroll Chiller

Cooling capacity: 140kW

Total power input: 44.5kW

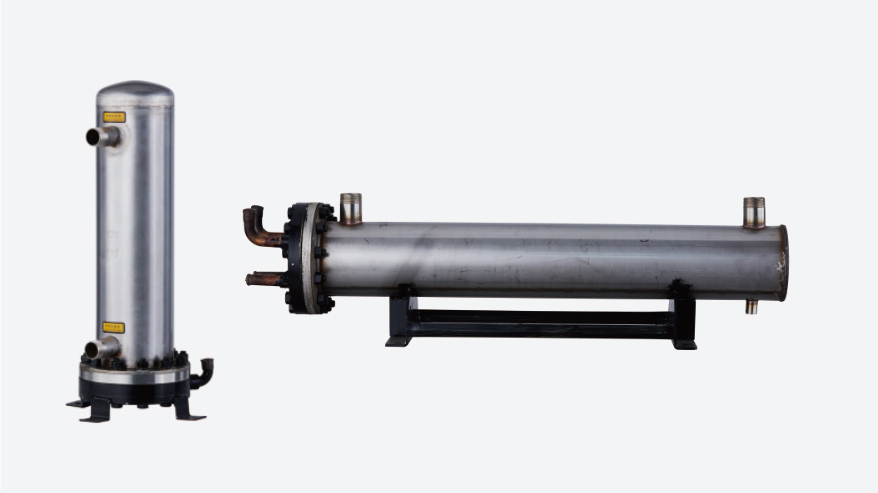

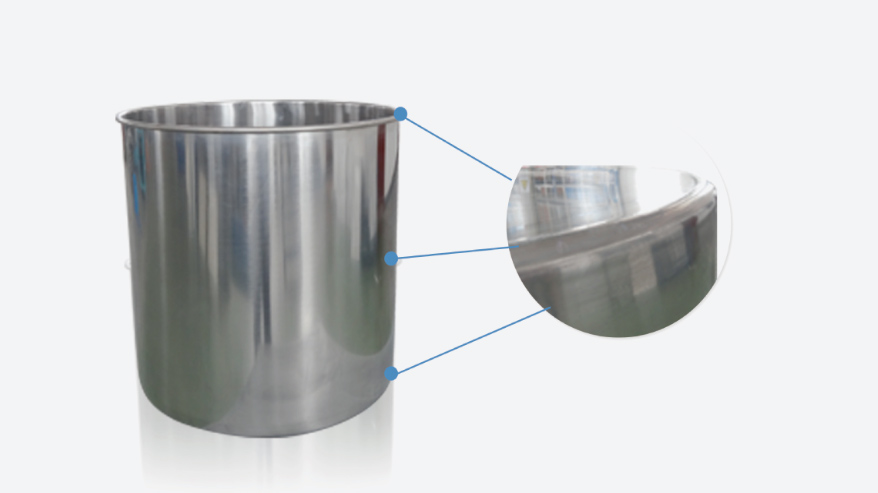

Evaporator type: Stainless steel shell and tube type

Evaporator water side pressure: 16 bar

Water flow rate: 24.0m³/h

Water pipe size: DN65

Noise: 72dB(A)

Cooling capacity: 140kW

Total power input: 44.5kW

Evaporator type: Stainless steel shell and tube type

Evaporator water side pressure: 16 bar

Water flow rate: 24.0m³/h

Water pipe size: DN65

Noise: 72dB(A)

Share:

I. Advantages

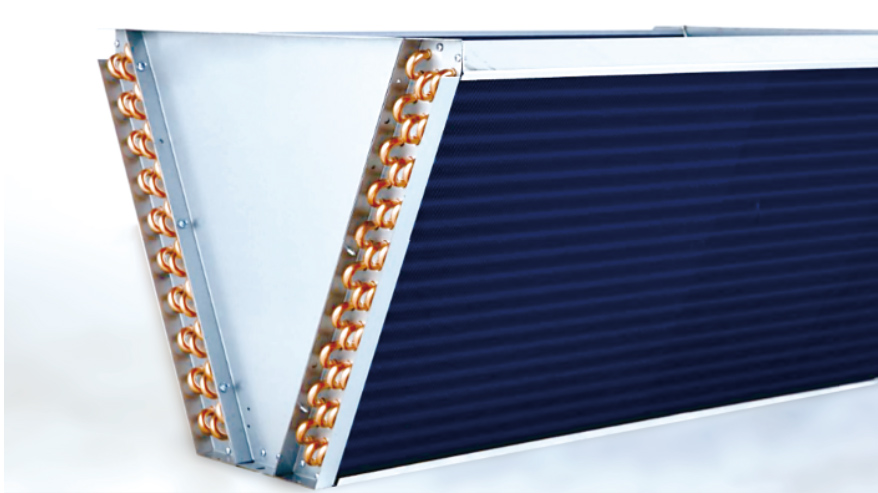

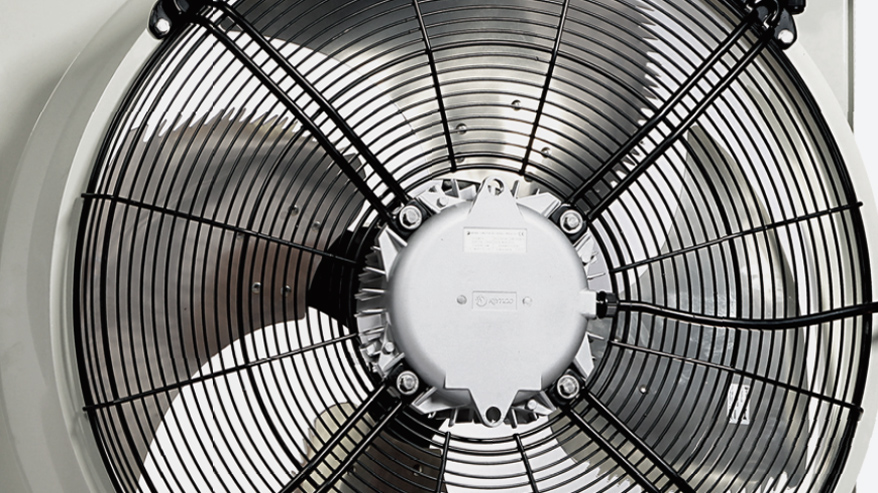

Air-cooled scroll chillers utilize a scroll compressor as their core, coupled with air cooling. Their strengths are concentrated in small and medium-sized cooling capacity applications. First, they offer excellent energy efficiency and stability. The scroll compressor has no reciprocating parts, resulting in low vibration and noise (operating noise ≤ 65dB). This high COP (cost-effective performance ratio) results in low long-term energy consumption and a low failure rate. Second, they are easy to install and maintain, eliminating the need for a cooling tower. The integrated design occupies a small footprint, requiring only daily cleaning of the condenser fins, resulting in low maintenance costs. Third, they offer flexible load adjustment, supporting 25%-100% step-by-step or stepless adjustment, making them suitable for fluctuating cooling capacity scenarios.

II. Applications

Electronics Industry: Cools precision equipment such as PCB soldering, SMT placement equipment, and semiconductor photolithography machines to prevent component failure due to high temperatures.

Plastics/Rubber Industry: Cools molds in injection molding machines and extruders to accelerate molding, ensure dimensional accuracy, and reduce scrap.

Mechanical Processing Industry: Cools spindles and cutting fluids in CNC machine tools, grinders, laser cutters, and other equipment to extend equipment life and improve machining accuracy.

Medical Industry: Provides a cooling source for the cooling systems of medical equipment such as MRI scanners and CT scanners.

New Energy Industry: Cools the heat dissipation systems of small energy storage batteries and charging stations to prevent battery degradation due to high temperatures or charging station overload.

Laboratory: Provides a stable low-temperature environment for precision instruments such as biological incubators, chemical reactors, and spectrometers to ensure accurate experimental data.

Food Processing: Cools food cold storage, baking equipment, and beverage production lines to ensure a low-temperature environment during food processing and storage.

I. Advantages

Air-cooled scroll chillers utilize a scroll compressor as their core, coupled with air cooling. Their strengths are concentrated in small and medium-sized cooling capacity applications. First, they offer excellent energy efficiency and stability. The scroll compressor has no reciprocating parts, resulting in low vibration and noise (operating noise ≤ 65dB). This high COP (cost-effective performance ratio) results in low long-term energy consumption and a low failure rate. Second, they are easy to install and maintain, eliminating the need for a cooling tower. The integrated design occupies a small footprint, requiring only daily cleaning of the condenser fins, resulting in low maintenance costs. Third, they offer flexible load adjustment, supporting 25%-100% step-by-step or stepless adjustment, making them suitable for fluctuating cooling capacity scenarios.

II. Applications

Electronics Industry: Cools precision equipment such as PCB soldering, SMT placement equipment, and semiconductor photolithography machines to prevent component failure due to high temperatures.

Plastics/Rubber Industry: Cools molds in injection molding machines and extruders to accelerate molding, ensure dimensional accuracy, and reduce scrap.

Mechanical Processing Industry: Cools spindles and cutting fluids in CNC machine tools, grinders, laser cutters, and other equipment to extend equipment life and improve machining accuracy.

Medical Industry: Provides a cooling source for the cooling systems of medical equipment such as MRI scanners and CT scanners.

New Energy Industry: Cools the heat dissipation systems of small energy storage batteries and charging stations to prevent battery degradation due to high temperatures or charging station overload.

Laboratory: Provides a stable low-temperature environment for precision instruments such as biological incubators, chemical reactors, and spectrometers to ensure accurate experimental data.

Food Processing: Cools food cold storage, baking equipment, and beverage production lines to ensure a low-temperature environment during food processing and storage.

| Item / Model | ICS-20A | ICS-25A | ICS-40A | ICS-50A | ||

| Cooling capacity | kW | 58.5 | 69.0 | 116 | 140 | |

| 10 ³ kcal/h | 50.3 | 59.3 | 100.0 | 120.0 | ||

| Power source | V/ph/Hz | 380/3/50 | ||||

| Total power input | kW | 18.9 | 21.8 | 37.8 | 44.5 | |

| Rated current | A | 37.0 | 42.0 | 69.0 | 81.0 | |

| Compressor | Type | Scroll type | ||||

| Power input | kW | 17.4 | 20.2 | 35.0 | 40.6 | |

| Evaporator | Type | Stainless steel shell and tube type | ||||

| Water side pressure | 16 bar | |||||

| Water flow rate | m³ /h | 10.0 | 11.8 | 20.0 | 24.0 | |

| L/min | 167 | 197 | 333 | 400 | ||

| Water pipe size | DN | 50 | 50 | 65 | ||

| Noise | dB(A) | 69 | 70 | 72 | 72 | |

| Weight | kg | 600 | 750 | 1100 | 1300 | |

| Dimension | Lenth | mm | 2080 | 2080 | 2200 | 2100 |

| Width | mm | 1050 | 1050 | 1200 | 1905 | |

| High | mm | 1820 | 1820 | 2135 | 2120 | |

| Item / Model | ICS-75A | ICS-100A | ICS-125A | ICS-150A | ||

| Cooling capacity | kW | 210.0 | 280.0 | 350.0 | 420.0 | |

| 10 ³ kcal/h | 180.6 | 240.8 | 301.0 | 361.2 | ||

| Power source | V/ph/Hz | 380/3/50 | ||||

| Total power input | kW | 65.5 | 87.0 | 109.0 | 131.0 | |

| Rated current | A | 120.0 | 160.0 | 200.0 | 240.0 | |

| Compressor | Type | Scroll type | ||||

| Power input | kW | 60.9 | 81.2 | 101.5 | 121.8 | |

| Evaporator | Type | Stainless steel shell and tube type | ||||

| Water side pressure | 16 bar | |||||

| Water flow rate | m³ /h | 36.1 | 48.2 | 60.2 | 72.3 | |

| L/min | 600 | 803 | 1003 | 1204 | ||

| Water pipe size | DN | 80 | 100 | |||

| Noise | dB(A) | 73 | 74 | 75 | 76 | |

| Weight | kg | 1850 | 2450 | 2950 | 3450 | |

| Dimension | Lenth | mm | 3155 | 4205 | 5255 | 6305 |

| Width | mm | 1905 | 1905 | 1905 | 1905 | |

| High | mm | 1920 | 1920 | 1920 | 1920 | |

Support customization

| Item / Model | ICS-20A | ICS-25A | ICS-40A | ICS-50A | ||

| Cooling capacity | kW | 58.5 | 69.0 | 116 | 140 | |

| 10 ³ kcal/h | 50.3 | 59.3 | 100.0 | 120.0 | ||

| Power source | V/ph/Hz | 380/3/50 | ||||

| Total power input | kW | 18.9 | 21.8 | 37.8 | 44.5 | |

| Rated current | A | 37.0 | 42.0 | 69.0 | 81.0 | |

| Compressor | Type | Scroll type | ||||

| Power input | kW | 17.4 | 20.2 | 35.0 | 40.6 | |

| Evaporator | Type | Stainless steel shell and tube type | ||||

| Water side pressure | 16 bar | |||||

| Water flow rate | m³ /h | 10.0 | 11.8 | 20.0 | 24.0 | |

| L/min | 167 | 197 | 333 | 400 | ||

| Water pipe size | DN | 50 | 50 | 65 | ||

| Noise | dB(A) | 69 | 70 | 72 | 72 | |

| Weight | kg | 600 | 750 | 1100 | 1300 | |

| Dimension | Lenth | mm | 2080 | 2080 | 2200 | 2100 |

| Width | mm | 1050 | 1050 | 1200 | 1905 | |

| High | mm | 1820 | 1820 | 2135 | 2120 | |

| Item / Model | ICS-75A | ICS-100A | ICS-125A | ICS-150A | ||

| Cooling capacity | kW | 210.0 | 280.0 | 350.0 | 420.0 | |

| 10 ³ kcal/h | 180.6 | 240.8 | 301.0 | 361.2 | ||

| Power source | V/ph/Hz | 380/3/50 | ||||

| Total power input | kW | 65.5 | 87.0 | 109.0 | 131.0 | |

| Rated current | A | 120.0 | 160.0 | 200.0 | 240.0 | |

| Compressor | Type | Scroll type | ||||

| Power input | kW | 60.9 | 81.2 | 101.5 | 121.8 | |

| Evaporator | Type | Stainless steel shell and tube type | ||||

| Water side pressure | 16 bar | |||||

| Water flow rate | m³ /h | 36.1 | 48.2 | 60.2 | 72.3 | |

| L/min | 600 | 803 | 1003 | 1204 | ||

| Water pipe size | DN | 80 | 100 | |||

| Noise | dB(A) | 73 | 74 | 75 | 76 | |

| Weight | kg | 1850 | 2450 | 2950 | 3450 | |

| Dimension | Lenth | mm | 3155 | 4205 | 5255 | 6305 |

| Width | mm | 1905 | 1905 | 1905 | 1905 | |

| High | mm | 1920 | 1920 | 1920 | 1920 | |

Support customization

Product Recommendation

ICS-40A Air Cooled Scroll Chiller-

ICS-40A Air Cooled Scroll Chiller

Cooling capacity: 116kW Total power input: 37.8kW Evaporator type: Stainless steel shell and tube type Evaporator water side pressure: 16 bar Water flow rate : 20.0m³/h Water pipe size : DN50 Noise : 72dB(A)

ICS-75A Air Cooled Scroll Chiller-

ICS-75A Air Cooled Scroll Chiller

Cooling capacity: 210.0kW Total power input: 65.5kW Evaporator type: Stainless steel shell and tube type Evaporator water side pressure: 16 bar Water flow rate : 36.1m³/h Water pipe size : DN80 Noise : 73dB(A)

ICS-100A Air Cooled Scroll Chiller-

ICS-100A Air Cooled Scroll Chiller

Cooling capacity: 280.0kW Total power input: 87.0kW Evaporator type: Stainless steel shell and tube type Evaporator water side pressure: 16 bar Water flow rate : 48.2m³/h Water pipe size : DN80 Noise : 74dB(A)

ICS-125A Air Cooled Scroll Chiller-

ICS-125A Air Cooled Scroll Chiller

Cooling capacity: 350.0kW Total power input: 109.0kW Evaporator type: Stainless steel shell and tube type Evaporator water side pressure: 16 bar Water flow rate : 60.2m³/h Water pipe size : DN100 Noise : 75dB(A)

ICS-150A Air Cooled Scroll Chiller-

ICS-150A Air Cooled Scroll Chiller

Cooling capacity: 420.0kW Total power input: 131.0kW Evaporator type: Stainless steel shell and tube type Evaporator water side pressure: 16 bar Water flow rate : 72.3m³/h Water pipe size : DN100 Noise : 76dB(A)

ICS-20A Air Cooled Scroll Chiller-

ICS-20A Air Cooled Scroll Chiller

Cooling capacity: 58.5kW Total power input: 18.9kW Evaporator type: Stainless steel shell and tube type Evaporator water side pressure: 16 bar Water flow rate : 10.0m³/h Water pipe size : DN50 Noise : 69dB(A)

ICS-25A Air Cooled Scroll Chiller-

ICS-25A Air Cooled Scroll Chiller

Cooling capacity: 69.0kW Total power input: 21.8kW Evaporator type: Stainless steel shell and tube type Evaporator water side pressure: 16 bar Water flow rate : 11.8m³/h Water pipe size : DN50 Noise : 70dB(A)

ICS-40A Air Cooled Scroll Chiller-

ICS-40A Air Cooled Scroll Chiller

Cooling capacity: 116kW Total power input: 37.8kW Evaporator type: Stainless steel shell and tube type Evaporator water side pressure: 16 bar Water flow rate : 20.0m³/h Water pipe size : DN50 Noise : 72dB(A)

ICS-75A Air Cooled Scroll Chiller-

ICS-75A Air Cooled Scroll Chiller

Cooling capacity: 210.0kW Total power input: 65.5kW Evaporator type: Stainless steel shell and tube type Evaporator water side pressure: 16 bar Water flow rate : 36.1m³/h Water pipe size : DN80 Noise : 73dB(A)

ICS-100A Air Cooled Scroll Chiller-

ICS-100A Air Cooled Scroll Chiller

Cooling capacity: 280.0kW Total power input: 87.0kW Evaporator type: Stainless steel shell and tube type Evaporator water side pressure: 16 bar Water flow rate : 48.2m³/h Water pipe size : DN80 Noise : 74dB(A)

ICS-125A Air Cooled Scroll Chiller-

ICS-125A Air Cooled Scroll Chiller

Cooling capacity: 350.0kW Total power input: 109.0kW Evaporator type: Stainless steel shell and tube type Evaporator water side pressure: 16 bar Water flow rate : 60.2m³/h Water pipe size : DN100 Noise : 75dB(A)

ICS-150A Air Cooled Scroll Chiller-

ICS-150A Air Cooled Scroll Chiller

Cooling capacity: 420.0kW Total power input: 131.0kW Evaporator type: Stainless steel shell and tube type Evaporator water side pressure: 16 bar Water flow rate : 72.3m³/h Water pipe size : DN100 Noise : 76dB(A)

ICS-20A Air Cooled Scroll Chiller-

ICS-20A Air Cooled Scroll Chiller

Cooling capacity: 58.5kW Total power input: 18.9kW Evaporator type: Stainless steel shell and tube type Evaporator water side pressure: 16 bar Water flow rate : 10.0m³/h Water pipe size : DN50 Noise : 69dB(A)

ICS-25A Air Cooled Scroll Chiller-

ICS-25A Air Cooled Scroll Chiller

Cooling capacity: 69.0kW Total power input: 21.8kW Evaporator type: Stainless steel shell and tube type Evaporator water side pressure: 16 bar Water flow rate : 11.8m³/h Water pipe size : DN50 Noise : 70dB(A)

ICS-40A Air Cooled Scroll Chiller-

ICS-40A Air Cooled Scroll Chiller

Cooling capacity: 116kW Total power input: 37.8kW Evaporator type: Stainless steel shell and tube type Evaporator water side pressure: 16 bar Water flow rate : 20.0m³/h Water pipe size : DN50 Noise : 72dB(A)

ICS-75A Air Cooled Scroll Chiller-

ICS-75A Air Cooled Scroll Chiller

Cooling capacity: 210.0kW Total power input: 65.5kW Evaporator type: Stainless steel shell and tube type Evaporator water side pressure: 16 bar Water flow rate : 36.1m³/h Water pipe size : DN80 Noise : 73dB(A)

ICS-100A Air Cooled Scroll Chiller-

ICS-100A Air Cooled Scroll Chiller

Cooling capacity: 280.0kW Total power input: 87.0kW Evaporator type: Stainless steel shell and tube type Evaporator water side pressure: 16 bar Water flow rate : 48.2m³/h Water pipe size : DN80 Noise : 74dB(A)

Give us a free quote

Submit this form and our sales representative will contact you soon.