【Digital Transformation】Warmly welcome the expert group from the Ministry of Industry and Information Technology to visit KANSA REFRIGERATION to witness the results of digital transformation

2025-04-22

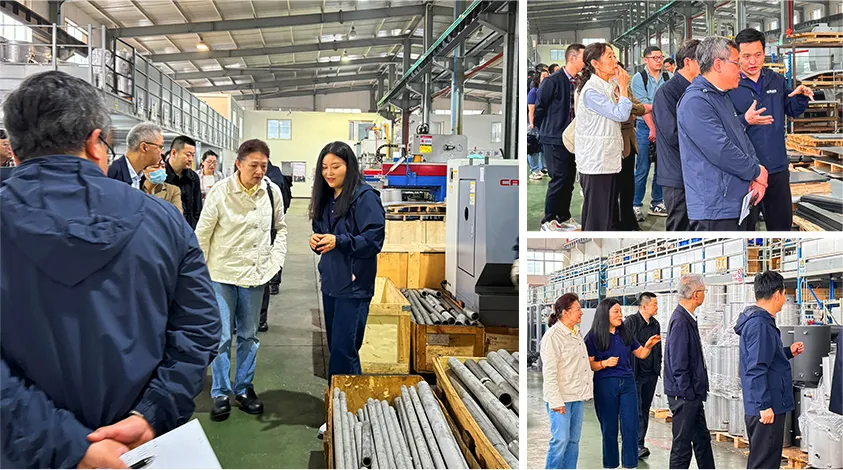

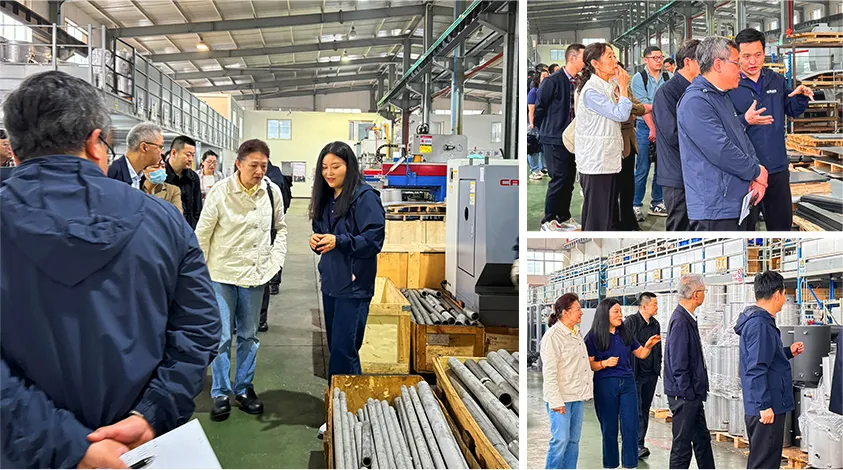

On April 22, 2025, the expert group of the Ministry of Industry and Information Technology of the People's Republic of China and the leaders of the city and district science and technology commissions visited KANSA REFRIGERATION.

The expert group conducted an acceptance inspection of the company's digital smart factory transformation project. Through on-site visits and discussions, they comprehensively evaluated KANSA REFRIGERATION's achievements in digital transformation. They also held in-depth discussions with the company's management and technical team on the future development direction of digital smart manufacturing, and witnessed KANSA REFRIGERATION's new breakthroughs in the field of digitalization.

Field investigation - Digital smart factory demonstrates its core strength

To ensure a safe and standardized visit, KANSA REFRIGERATION provided the expert group with labor protection supplies and strictly adhered to the safety management requirements of the production workshop during the reception. During the on-site factory visit, the expert group focused on the demonstration of intelligent and automated equipment in digital application scenarios.

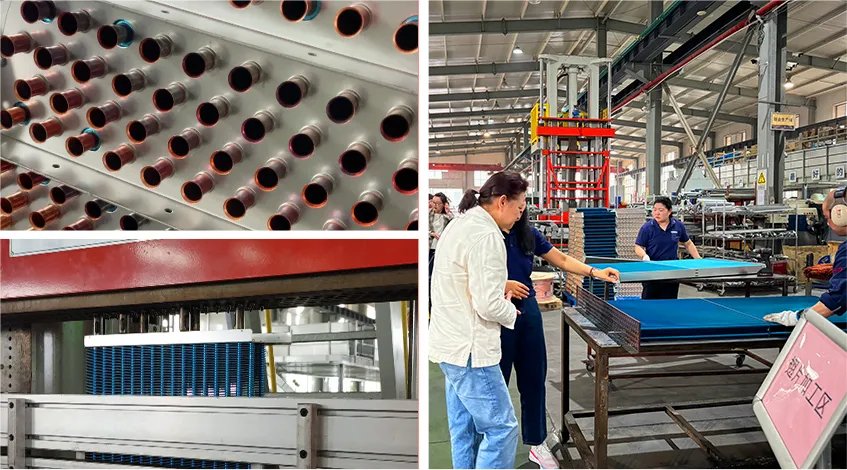

Robot automatic welding water tank production process

KANSA REFRIGERATION uses digital construction to drive quality manufacturing upgrades, greatly improving production capacity, flexibility, scalability, economic benefits and product quality.

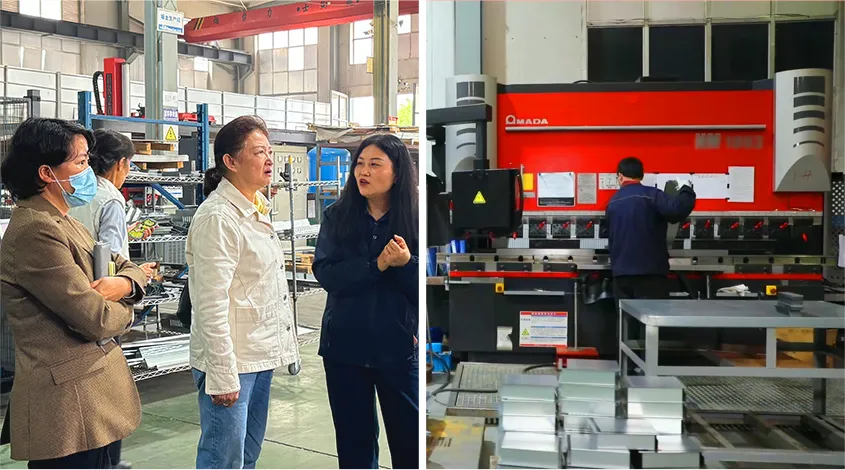

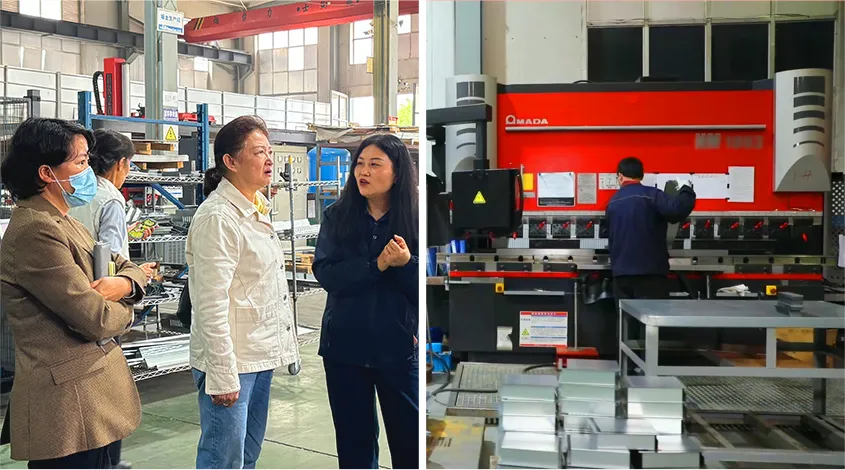

High-end sheet metal processing equipment

Swiss Bystronic bending robot: High-precision bending technology, sheet metal processing accuracy of ±0.004mm, achieving one-time forming of complex sheet metal parts, automatic stacking, and significantly improving efficiency.

AMADA automatic bending

Automatic loading and unloading of laser equipment

AMADA automatic bending and automatic loading and unloading of laser equipment: By linking laser cutting and automatic bending, manual intervention is reduced and production flexibility is improved.

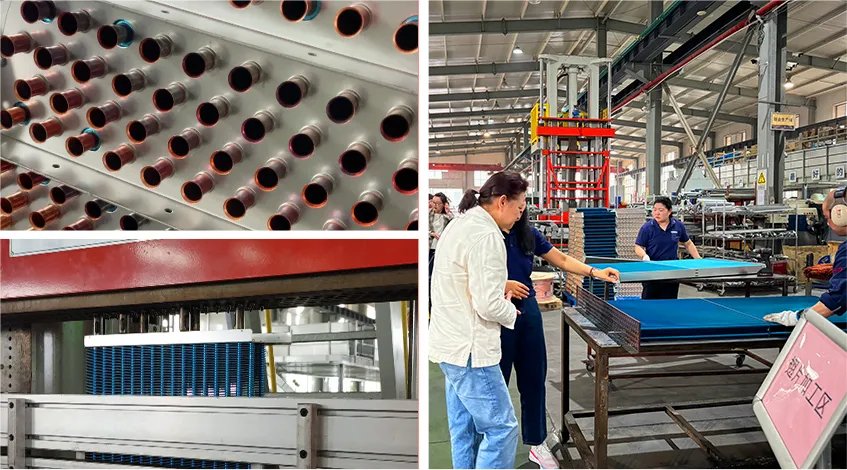

Homemade evaporator and condenser

KANSA REFRIGERATION's independently produced innovative V-shaped fin condenser adopts efficient copper tube design and mechanical tube expansion process to ensure high performance and reliability.

Digital production management

In the industrial chiller assembly workshop, the expert team reviewed the digital production process. After each process is completed, the production status can be checked in real time, enabling transparent and traceable production management.

KANSA REFRIGERATION uses digital construction to drive quality manufacturing upgrades, significantly improving production efficiency, product quality and equipment utilization, while reducing operating costs, fully demonstrating the economic benefits of digital "smart manufacturing" upgrades.

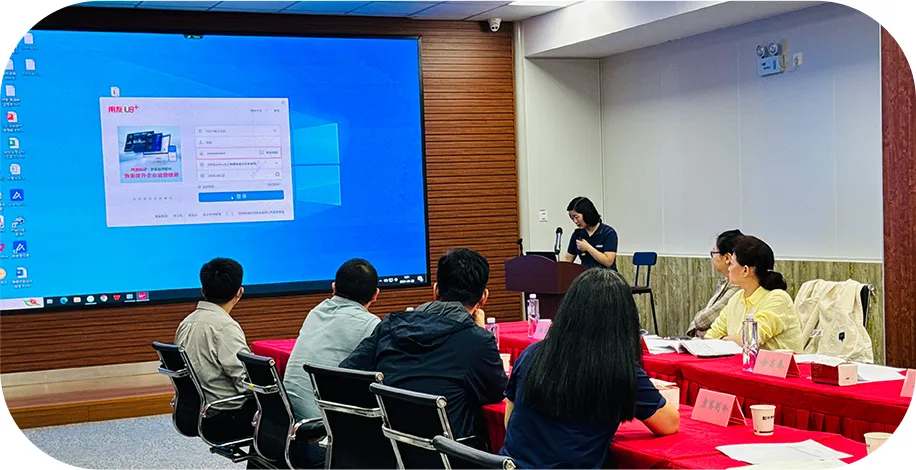

Discussion and Exchange

Construction, results, and future planning of digital upgrades and transformations

After the inspection, the two sides held a digital transformation acceptance exchange meeting in the conference room. KANSA REFRIGERATION leaders gave a detailed report on the company's profile, technological innovation, digital construction achievements, and future development:

Enterprise Technology and Product Innovation

KANSA REFRIGERATION has been deeply engaged in the industrial refrigeration field for 20 years. Since the promulgation of the 14th Five-Year Plan for Intelligent Manufacturing in 2021, the company has been actively aligning with national policies and incorporating digital transformation into its strategic development plan.

In recent years, the company has achieved numerous technological breakthroughs in the digital intelligent manufacturing upgrade of industrial chillers. For three consecutive years, it has been awarded the titles of Shanghai High-Tech Enterprise, Specialized and New Enterprise, and Innovative Small and Medium-sized Enterprise, as well as "Pudong R&D Institution and District-level Smart Factory." The company holds over 100 invention patents.

Through process improvements, the company has developed a variety of chiller products, successfully achieving flow control of ±0.05L/min and precise temperature control of ±0.05°C for industrial chillers. The company has also developed a new energy test chiller, improving industry performance, promoting energy conservation and environmental protection, and enhancing core competitiveness.

Digital construction planning and results

A PDM system was introduced and integrated with SolidWorks design software, enabling centralized management of product designs and process documents.

A desktop cloud platform was deployed to centrally manage and operate enterprise data, establishing a secure enterprise office channel through the desktop cloud.

The deployment of digital systems such as UFIDA ERP and OA enabled a fully digitized model for production task dispatching, reporting, and progress tracking, further enhancing procurement, sales, supply chain, financial management, and cost control capabilities.

Goal: Transform from traditional manufacturing to digital "intelligent manufacturing" and build a big data-driven production and operations system.

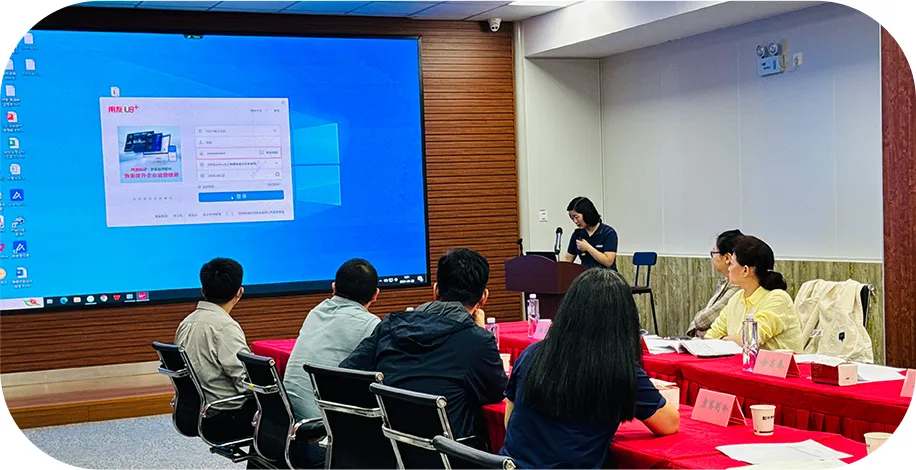

Digital system demonstration

The company's operations manager demonstrated on-site the application of digital tools such as PDM systems, production dashboards, and equipment management platforms, presenting the real-time operating status of the factory through data visualization.

Expert guidance: Firmly follow the direction of digital transformation

The expert group of the Ministry of Industry and Information Technology of China highly praised the digital transformation results of KANSA REFRIGERATION. This digital transformation has been very successful and is the most representative successful case of digital transformation of small and medium-sized enterprises.

The report also noted that digital transformation is the only path to high-quality development in the manufacturing industry, and that companies must continue to deepen their application of digital technologies.

It also recommended further exploring the integration of technologies like artificial intelligence and digital twins with production scenarios, striving to become a benchmark for pilot cities in digital transformation.

Looking to the future: Striving to become a "digital beacon" in the field of industrial refrigeration

KANSA REFRIGERATION stated that digital transformation is a long-term strategy with no end point, and the construction of smart factories is always on the way. The company will take this acceptance as a starting point and continue to optimize the construction of smart factories. At this stage, it strives to become an industry benchmark for digital transformation city pilots. In the future, it is committed to becoming a "digital lighthouse" in the field of industrial refrigeration, providing customers with more efficient and intelligent refrigeration solutions, and helping China's manufacturing upgrade to "China's intelligent manufacturing."

On April 22, 2025, the expert group of the Ministry of Industry and Information Technology of the People's Republic of China and the leaders of the city and district science and technology commissions visited KANSA REFRIGERATION.

The expert group conducted an acceptance inspection of the company's digital smart factory transformation project. Through on-site visits and discussions, they comprehensively evaluated KANSA REFRIGERATION's achievements in digital transformation. They also held in-depth discussions with the company's management and technical team on the future development direction of digital smart manufacturing, and witnessed KANSA REFRIGERATION's new breakthroughs in the field of digitalization.

Field investigation - Digital smart factory demonstrates its core strength

To ensure a safe and standardized visit, KANSA REFRIGERATION provided the expert group with labor protection supplies and strictly adhered to the safety management requirements of the production workshop during the reception. During the on-site factory visit, the expert group focused on the demonstration of intelligent and automated equipment in digital application scenarios.

Robot automatic welding water tank production process

KANSA REFRIGERATION uses digital construction to drive quality manufacturing upgrades, greatly improving production capacity, flexibility, scalability, economic benefits and product quality.

High-end sheet metal processing equipment

Swiss Bystronic bending robot: High-precision bending technology, sheet metal processing accuracy of ±0.004mm, achieving one-time forming of complex sheet metal parts, automatic stacking, and significantly improving efficiency.

AMADA automatic bending

Automatic loading and unloading of laser equipment

AMADA automatic bending and automatic loading and unloading of laser equipment: By linking laser cutting and automatic bending, manual intervention is reduced and production flexibility is improved.

Homemade evaporator and condenser

KANSA REFRIGERATION's independently produced innovative V-shaped fin condenser adopts efficient copper tube design and mechanical tube expansion process to ensure high performance and reliability.

Digital production management

In the industrial chiller assembly workshop, the expert team reviewed the digital production process. After each process is completed, the production status can be checked in real time, enabling transparent and traceable production management.

KANSA REFRIGERATION uses digital construction to drive quality manufacturing upgrades, significantly improving production efficiency, product quality and equipment utilization, while reducing operating costs, fully demonstrating the economic benefits of digital "smart manufacturing" upgrades.

Discussion and Exchange

Construction, results, and future planning of digital upgrades and transformations

After the inspection, the two sides held a digital transformation acceptance exchange meeting in the conference room. KANSA REFRIGERATION leaders gave a detailed report on the company's profile, technological innovation, digital construction achievements, and future development:

Enterprise Technology and Product Innovation

KANSA REFRIGERATION has been deeply engaged in the industrial refrigeration field for 20 years. Since the promulgation of the 14th Five-Year Plan for Intelligent Manufacturing in 2021, the company has been actively aligning with national policies and incorporating digital transformation into its strategic development plan.

In recent years, the company has achieved numerous technological breakthroughs in the digital intelligent manufacturing upgrade of industrial chillers. For three consecutive years, it has been awarded the titles of Shanghai High-Tech Enterprise, Specialized and New Enterprise, and Innovative Small and Medium-sized Enterprise, as well as "Pudong R&D Institution and District-level Smart Factory." The company holds over 100 invention patents.

Through process improvements, the company has developed a variety of chiller products, successfully achieving flow control of ±0.05L/min and precise temperature control of ±0.05°C for industrial chillers. The company has also developed a new energy test chiller, improving industry performance, promoting energy conservation and environmental protection, and enhancing core competitiveness.

Digital construction planning and results

A PDM system was introduced and integrated with SolidWorks design software, enabling centralized management of product designs and process documents.

A desktop cloud platform was deployed to centrally manage and operate enterprise data, establishing a secure enterprise office channel through the desktop cloud.

The deployment of digital systems such as UFIDA ERP and OA enabled a fully digitized model for production task dispatching, reporting, and progress tracking, further enhancing procurement, sales, supply chain, financial management, and cost control capabilities.

Goal: Transform from traditional manufacturing to digital "intelligent manufacturing" and build a big data-driven production and operations system.

Digital system demonstration

The company's operations manager demonstrated on-site the application of digital tools such as PDM systems, production dashboards, and equipment management platforms, presenting the real-time operating status of the factory through data visualization.

Expert guidance: Firmly follow the direction of digital transformation

The expert group of the Ministry of Industry and Information Technology of China highly praised the digital transformation results of KANSA REFRIGERATION. This digital transformation has been very successful and is the most representative successful case of digital transformation of small and medium-sized enterprises.

The report also noted that digital transformation is the only path to high-quality development in the manufacturing industry, and that companies must continue to deepen their application of digital technologies.

It also recommended further exploring the integration of technologies like artificial intelligence and digital twins with production scenarios, striving to become a benchmark for pilot cities in digital transformation.

Looking to the future: Striving to become a "digital beacon" in the field of industrial refrigeration

KANSA REFRIGERATION stated that digital transformation is a long-term strategy with no end point, and the construction of smart factories is always on the way. The company will take this acceptance as a starting point and continue to optimize the construction of smart factories. At this stage, it strives to become an industry benchmark for digital transformation city pilots. In the future, it is committed to becoming a "digital lighthouse" in the field of industrial refrigeration, providing customers with more efficient and intelligent refrigeration solutions, and helping China's manufacturing upgrade to "China's intelligent manufacturing."