【Hardcore Strength】The Shanghai Technology Exchange and a panel of experts from the Review Committee visited KANSA REFRIGERATION to evaluate its high-precision temperature and flow control chiller intelligent monitoring system.

2025-05-22

On May 22, 2025, the Shanghai Technology Exchange, in accordance with the standards and procedures for scientific and technological achievement evaluation, organized a panel of five experts in relevant technical fields and industry to conduct an on-site evaluation of the high-precision temperature and flow control chiller intelligent monitoring system developed by Shanghai KANSA Refrigeration Equipment Co., Ltd.

Technological Dialogue, Innovation Breakthrough

At the special report meeting, the KANSA REFRIGERATION technical team systematically presented the core value of the scientific and technological achievements of high-precision temperature control units with "innovation-driven and intelligent empowerment" as the main line:

01 Breaking through industry pain points

As the semiconductor manufacturing industry continues to grow in demand, the accuracy and reliability of temperature control are becoming increasingly stringent. Core processes such as lithography and etching are particularly sensitive to temperature fluctuations of ±0.1°C, which directly impacts chip quality and production costs.

Traditional temperature control equipment faces problems such as low precision, slow response, and high energy consumption. It cannot meet the high-precision requirements of semiconductor manufacturing and achieve precise regulation and dynamic optimization. High-end temperature control equipment relies on imports, which is costly and risky. Therefore, the replacement of domestic high-precision temperature control units is a key demand of the industry.

02 Independent Innovation Breakthrough

The reliability modeling and predictive maintenance system based on Monte Carlo simulation + adaptive fuzzy PID compound control system achieves ultra-precise temperature control of ±0.05℃ under all working conditions.

03 Project advancement

The temperature control accuracy surpasses that of comparable products in all aspects, filling the gap in precision temperature control technology under high dynamic load scenarios and reaching the international advanced level.

04 Market Application Prospects

It has successfully served high-end fields such as semiconductors, biomedicine, and laboratory precision manufacturing.

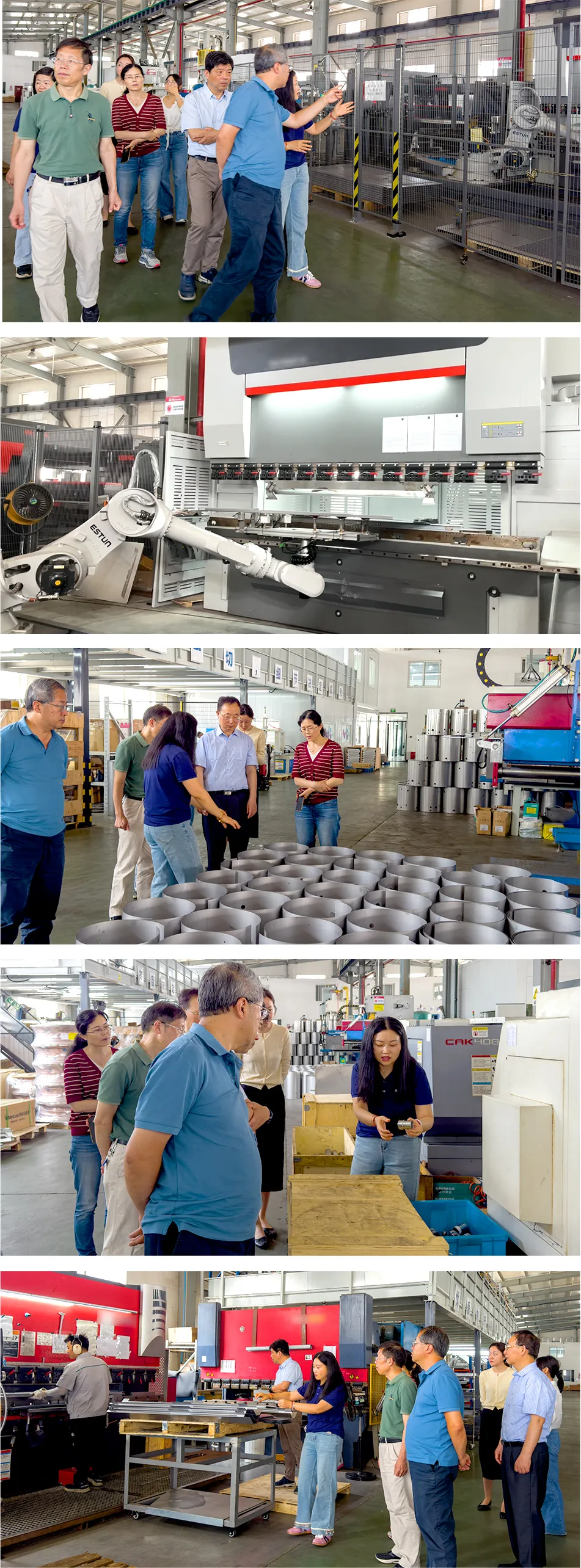

Seeing is believing, hardcore verification

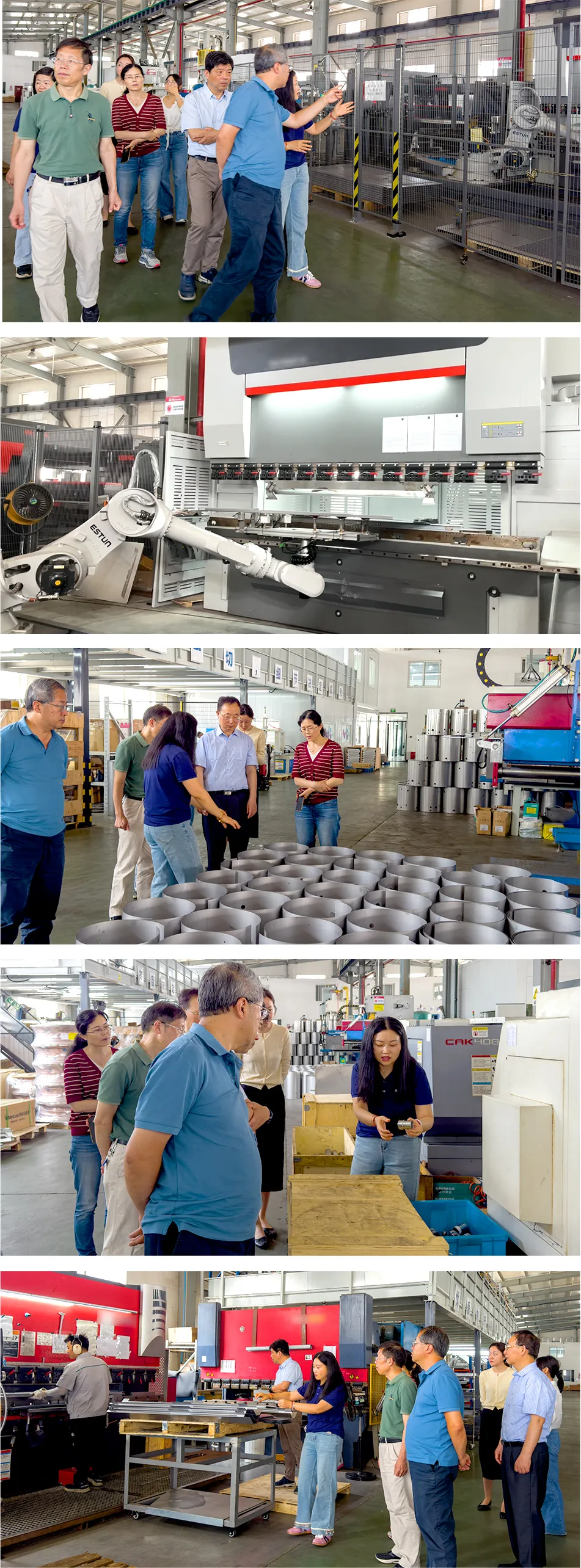

Theoretical data needs to be tested in practice! The expert review team then visited the KANSA REFRIGERATION smart factory for a field trip.

01 Core Equipment

02 Process Control

The finned condenser adopts fully automatic tube expansion technology, and the heat exchange efficiency is 1.2 times the industry standard.

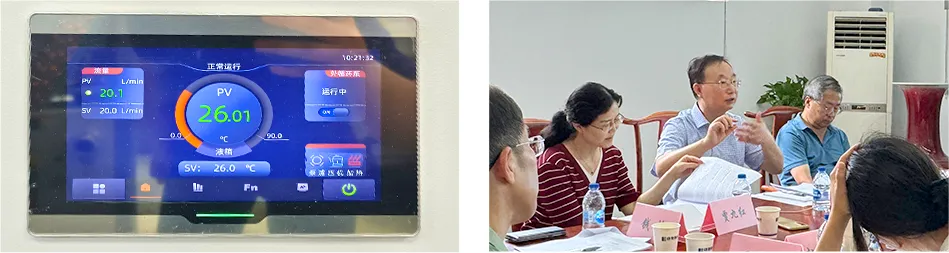

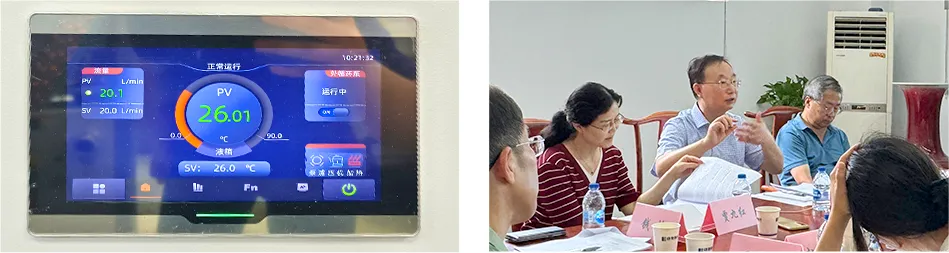

03 System Demonstration

Our technicians demonstrated the temperature control accuracy of the high-precision temperature control unit on site. The target temperature was set at 26.00℃ on site, and the intelligent monitoring screen jumped in real time: 26.03℃→26.01℃→26.00℃

After the equipment has been running for 5 minutes, the panel display and temperature curve are always stable within the range of ±0.05℃ of the set value.

Professional Evaluation: Recognition and Conclusion

During the review phase of the meeting, the expert group gave conclusions from three dimensions:

01 Technological Innovation

The high-precision temperature and flow control chiller intelligent monitoring system achieves wide temperature range control from -40℃ to 110℃.

02 Technology Maturity

A high-precision temperature control technology has been developed to achieve a temperature control accuracy of ±0.05°C under all working conditions.

03 Application Advantages

A high-precision flow control method was developed that combines the flexibility of fuzzy control with the accuracy of PID (1~30 L/min) ±0.1 L/min.

The expert committee believes that the overall technical level of the project results has reached the domestic leading and international advanced level, and agrees that the project has passed the scientific and technological achievement evaluation.

On May 22, 2025, the Shanghai Technology Exchange, in accordance with the standards and procedures for scientific and technological achievement evaluation, organized a panel of five experts in relevant technical fields and industry to conduct an on-site evaluation of the high-precision temperature and flow control chiller intelligent monitoring system developed by Shanghai KANSA Refrigeration Equipment Co., Ltd.

Technological Dialogue, Innovation Breakthrough

At the special report meeting, the KANSA REFRIGERATION technical team systematically presented the core value of the scientific and technological achievements of high-precision temperature control units with "innovation-driven and intelligent empowerment" as the main line:

01 Breaking through industry pain points

As the semiconductor manufacturing industry continues to grow in demand, the accuracy and reliability of temperature control are becoming increasingly stringent. Core processes such as lithography and etching are particularly sensitive to temperature fluctuations of ±0.1°C, which directly impacts chip quality and production costs.

Traditional temperature control equipment faces problems such as low precision, slow response, and high energy consumption. It cannot meet the high-precision requirements of semiconductor manufacturing and achieve precise regulation and dynamic optimization. High-end temperature control equipment relies on imports, which is costly and risky. Therefore, the replacement of domestic high-precision temperature control units is a key demand of the industry.

02 Independent Innovation Breakthrough

The reliability modeling and predictive maintenance system based on Monte Carlo simulation + adaptive fuzzy PID compound control system achieves ultra-precise temperature control of ±0.05℃ under all working conditions.

03 Project advancement

The temperature control accuracy surpasses that of comparable products in all aspects, filling the gap in precision temperature control technology under high dynamic load scenarios and reaching the international advanced level.

04 Market Application Prospects

It has successfully served high-end fields such as semiconductors, biomedicine, and laboratory precision manufacturing.

Seeing is believing, hardcore verification

Theoretical data needs to be tested in practice! The expert review team then visited the KANSA REFRIGERATION smart factory for a field trip.

01 Core Equipment

02 Process Control

The finned condenser adopts fully automatic tube expansion technology, and the heat exchange efficiency is 1.2 times the industry standard.

03 System Demonstration

Our technicians demonstrated the temperature control accuracy of the high-precision temperature control unit on site. The target temperature was set at 26.00℃ on site, and the intelligent monitoring screen jumped in real time: 26.03℃→26.01℃→26.00℃

After the equipment has been running for 5 minutes, the panel display and temperature curve are always stable within the range of ±0.05℃ of the set value.

Professional Evaluation: Recognition and Conclusion

During the review phase of the meeting, the expert group gave conclusions from three dimensions:

01 Technological Innovation

The high-precision temperature and flow control chiller intelligent monitoring system achieves wide temperature range control from -40℃ to 110℃.

02 Technology Maturity

A high-precision temperature control technology has been developed to achieve a temperature control accuracy of ±0.05°C under all working conditions.

03 Application Advantages

A high-precision flow control method was developed that combines the flexibility of fuzzy control with the accuracy of PID (1~30 L/min) ±0.1 L/min.

The expert committee believes that the overall technical level of the project results has reached the domestic leading and international advanced level, and agrees that the project has passed the scientific and technological achievement evaluation.