Innovative Strength Recognized Again! KANSA Refrigeration’s “Water‑Cooled Industrial Chiller” Honored with Shanghai High‑Tech Achievement Transformation Project Certification

2026-01-08

Honors Affirmed

KANSA Refrigeration Awarded the Shanghai High‑Tech Achievement Transformation Certificate

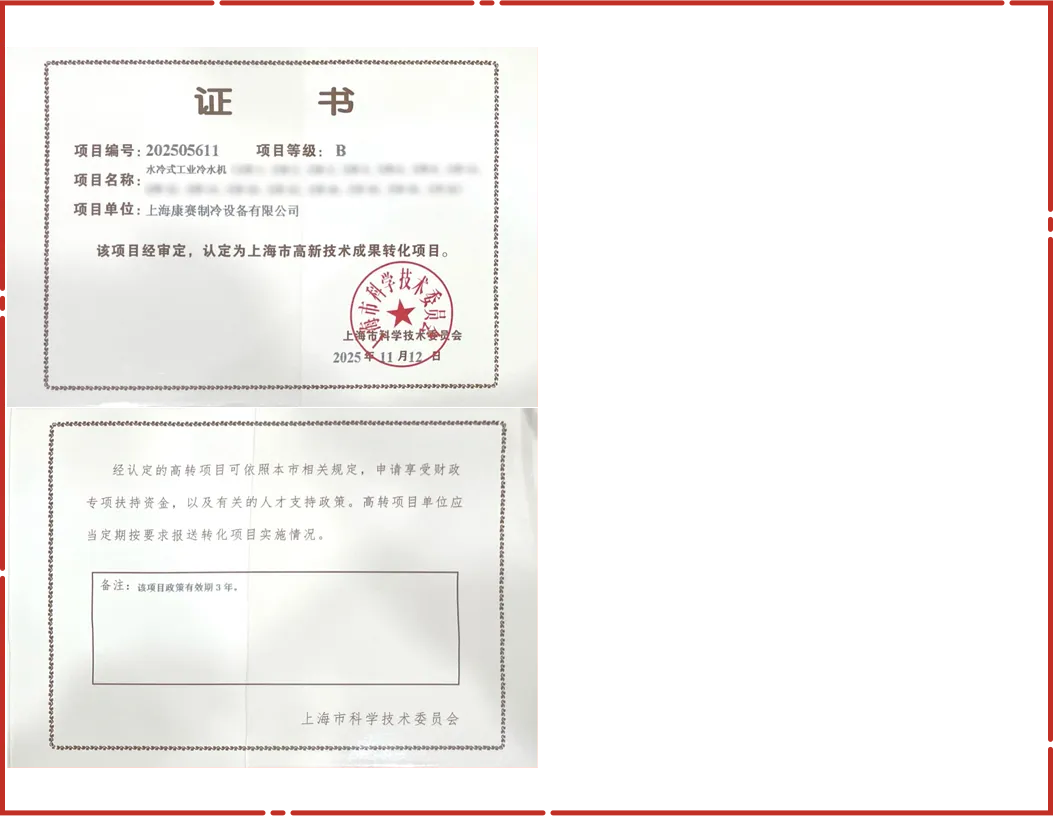

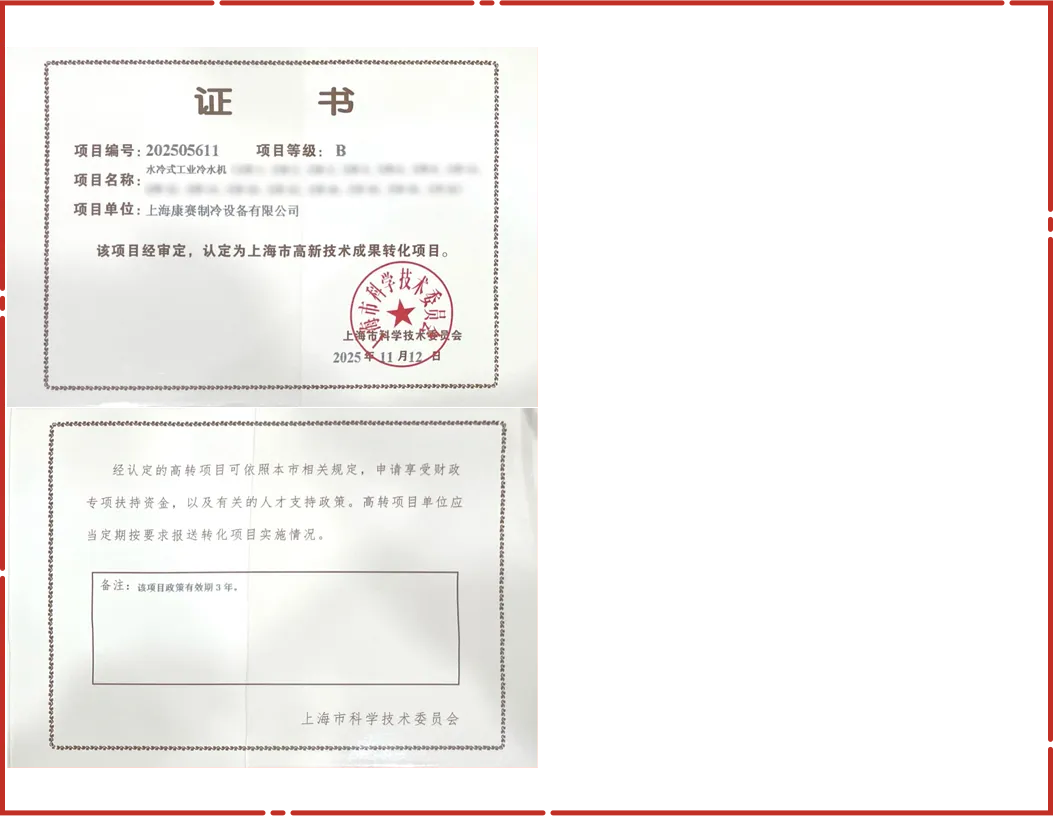

Recently, KANSA Refrigeration’s independently developed“Water‑Cooled Industrial Chiller” (Project No.: 202505611)stood out among numerous projects and successfully obtained the “Shanghai High‑Tech Achievement Transformation Project Certificate” issued by the Shanghai Municipal Science and Technology Commission.

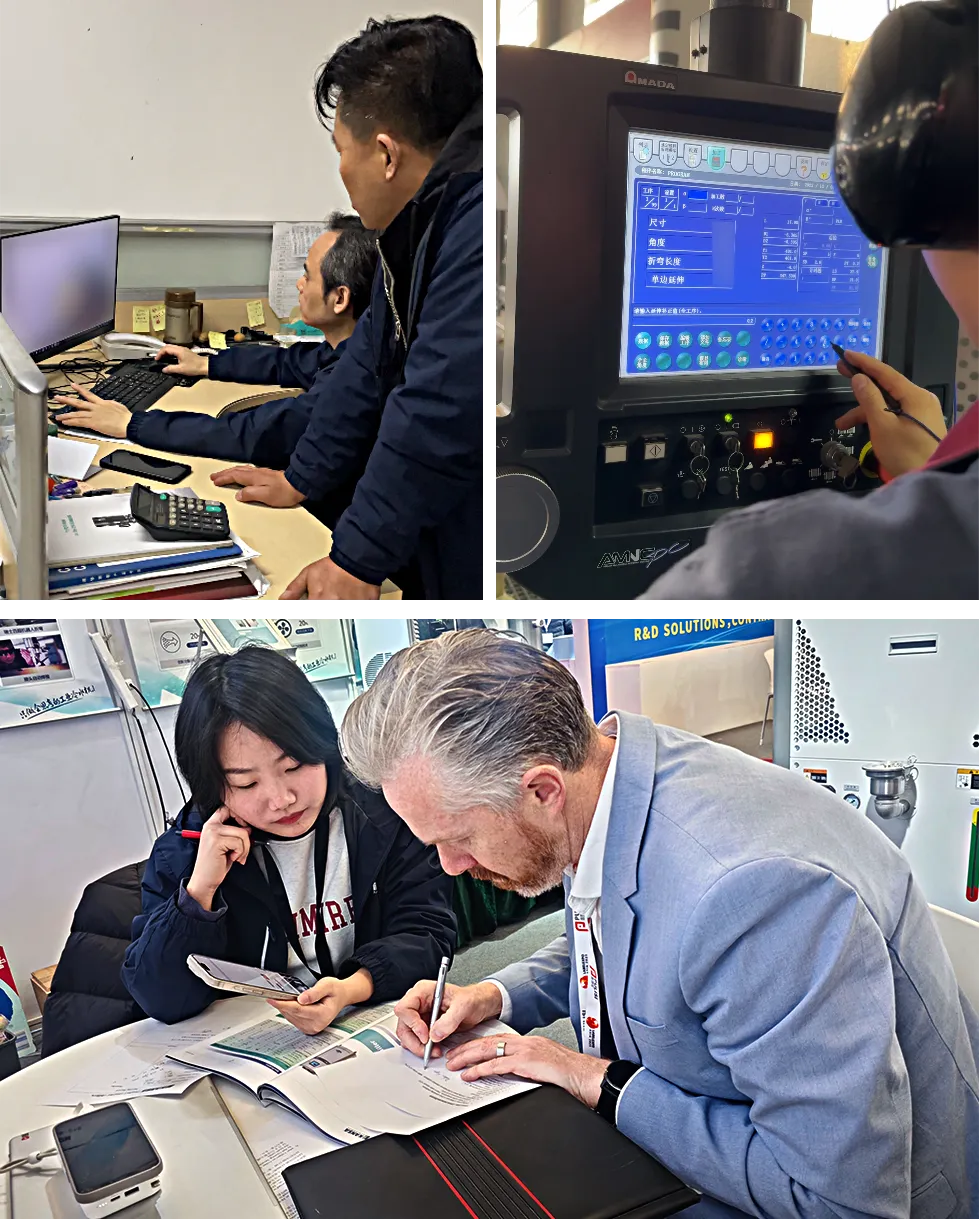

This achievement not only reaffirms KANSA Refrigeration’s R&D strength but also marks a solid and crucial step forward in our journey to transform cutting‑edge technology into practical productivity and drive the industrial refrigeration industry toward high‑end and intelligent upgrading.

Breaking Through

High‑Precision Innovation Addressing Industry Pain Points

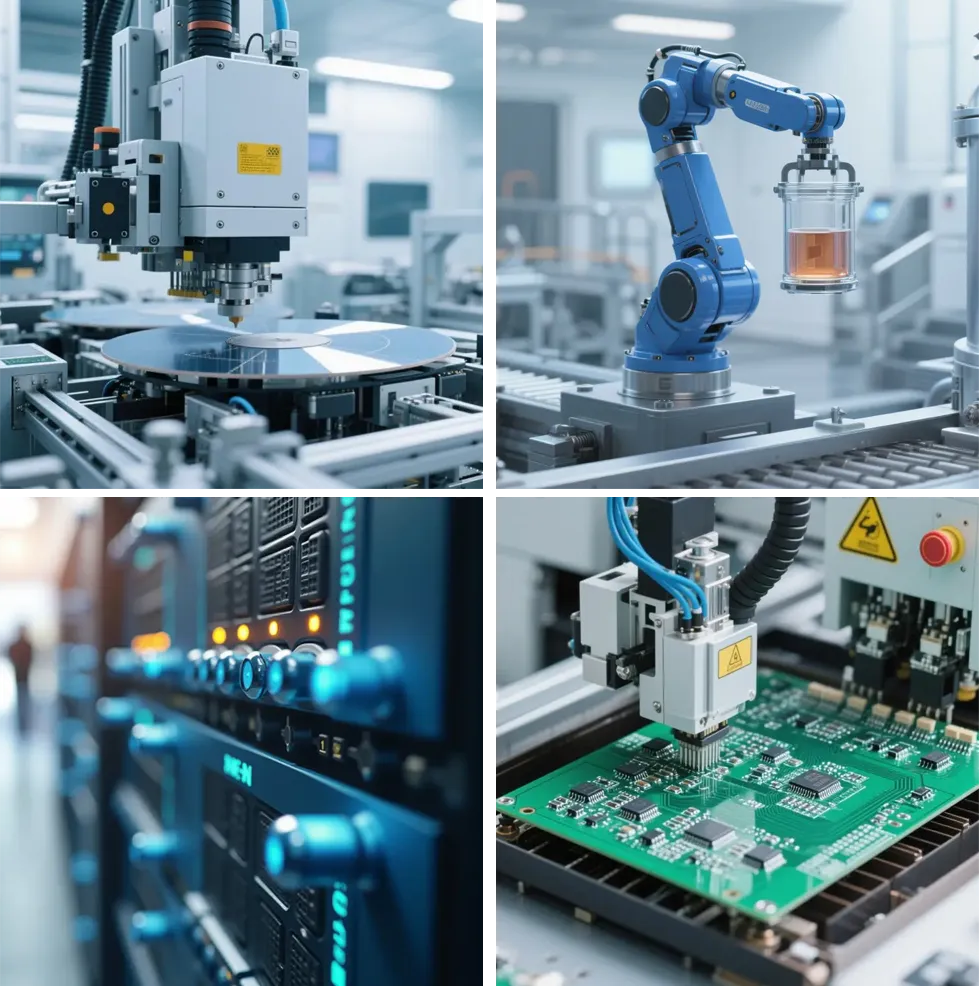

As global manufacturing upgrades, temperature control equipment is facing unprecedentedly high requirements. In advanced fields such as semiconductor manufacturing, biopharmaceuticals, and precision optics, production stability and product yield often depend on temperature fluctuations as precise as ±0.05℃. Traditional chillers have shown limitations in temperature control accuracy, energy consumption, and wide‑temperature adaptability, creating a market demand for more precise, efficient, and reliable solutions.

KANSA Refrigeration’s certified project directly responds to this era’s needs. Our “Water‑Cooled Industrial Chiller” is not a simple product iteration but a comprehensive innovation spanning core algorithms to system architecture.

Core Breakthrough 1: Extreme Temperature Control, Breaking Import Dependence

The project pioneered the “Non‑Stop Refrigerant Flow Control Algorithm,” which dynamically optimizes valve opening based on real‑time operating parameters to precisely match refrigerant flow with instantaneous loads. This achieves an exceptional temperature control accuracy of ±0.05℃ across the entire operating range of -40℃ to 110℃. As the first domestically mature industrial chiller to reach this precision level, it successfully breaks the long‑standing reliance on international brands in high‑end fields such as semiconductor wafer dicing.

Core Breakthrough 2: Intelligent Coordination, Balancing Efficiency and Stability

We integrated fuzzy PID control technology with an innovative water tank system design. The fuzzy algorithm enhances the system’s adaptability, while the PID algorithm ensures precise adjustment. Combined with circumferentially distributed temperature sensors and a unique flow channel design, the system rapidly eliminates temperature overshoot and achieves a flow control accuracy of ±0.1L/min across a wide flow range of 1–30L/min, ensuring stable operation even at ultra‑high temperature control precision.

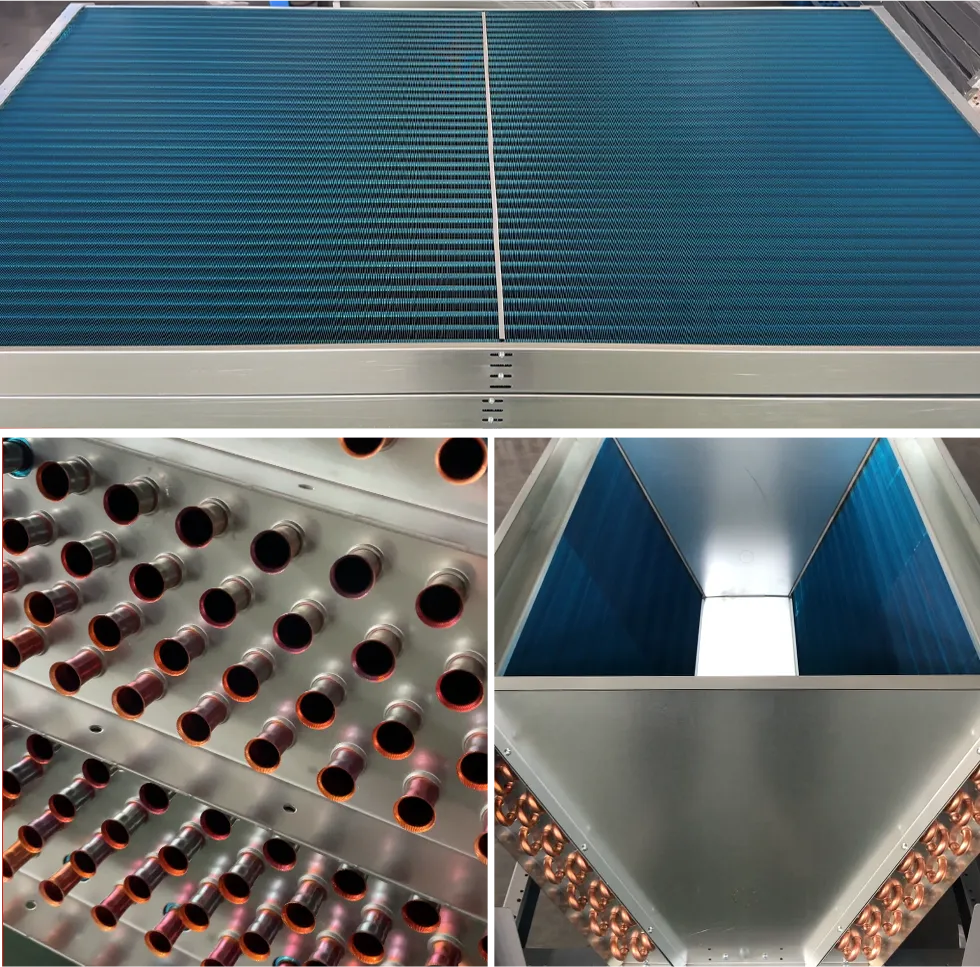

Core Breakthrough 3: High Energy Efficiency, Setting a New Benchmark

Through advanced condensation and integrated refrigeration pipeline technology, the project optimizes the internal structure of the condenser, significantly improving heat exchange efficiency. The final product achieves leading domestic cooling efficiency at the same power level, substantially reducing long‑term operating costs for customers.

Accumulated Strength

A Comprehensive Technological Moat

True innovation is reflected in every detail designed to enhance user value. This project has built a comprehensive technological moat covering core performance, maintenance convenience, and long‑term reliability:

Modular and Easy‑to‑Maintain Design:

Reduces the average repair time to less than 30 minutes. The supporting installation structure effectively reduces vibration and improves heat dissipation, enhancing operational stability.

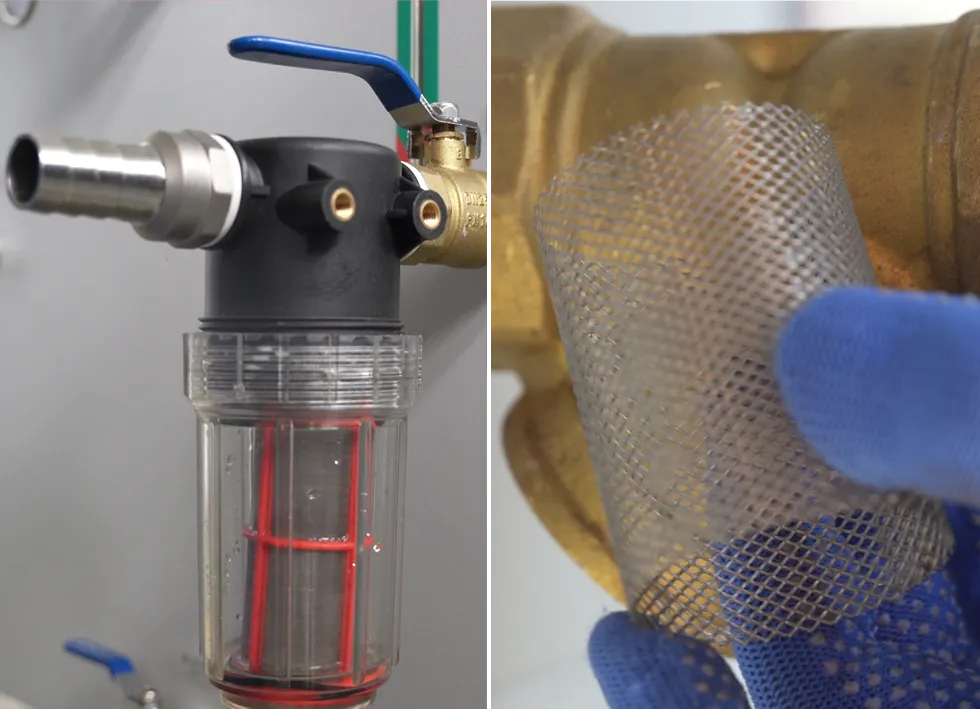

Self‑Cleaning Pre‑installed Structure:

Automatically removes internal fouling, greatly improving maintenance convenience and cleanliness while ensuring long‑term performance.

Strong Intellectual Property Foundation:

Related technologies have obtained 2 national invention patents (“A High‑Precision Temperature Control Industrial Chiller” and “An Easy‑to‑Maintain Chiller”) and 2 utility model patents, providing strong IP protection for the product.

After rigorous testing and evaluation by authoritative institutions, the product’s technical level has reached leading domestic and advanced international standards.

Broad Prospects

Empowering Industrial Upgrading and Driving a Green Future

This achievement transformation is not only the realization of technology but also the key to unlocking a vast market.

Precise Market Positioning:

The product targets strategically emerging industries with extreme temperature control requirements, such as semiconductor manufacturing, biomedicine, data centers, and precision electronics. With the expansion of domestic semiconductor production capacity and the wave of localization, the prospects are extremely promising.

Significant Competitive Advantages:

Compared with top international brands, our product achieves equal or higher precision with lower energy consumption, a wider temperature range, and strong cost‑effectiveness. Compared with leading domestic products, we have surpassed key indicators. This gives us powerful import substitution capabilities and strong market competitiveness.

Far‑Reaching Social Benefits:

The industrialization of this project will drive technological upgrades in the upstream supply chain and promote the development of high‑end manufacturing. Its excellent energy efficiency directly helps downstream enterprises reduce energy consumption, supporting the country’s “Dual Carbon” goals. Additionally, the entire chain from R&D to production and sales will create numerous high‑quality jobs, achieving both economic and social benefits.

Technology as the Foundation, Innovation for the Future

Since its establishment in 2006, Shanghai KANSA Refrigeration Equipment Co., Ltd. has been committed to the R&D and innovation of industrial refrigeration technology. The company’s main products include industrial chillers, high‑low temperature integrated machines, cabinet air conditioners, oil coolers, and new innovative products such as new energy temperature control units and immersion‑type cutting fluid coolers. These products are widely used in industries such as industry, new energy, injection molding, food processing, and medical care, and have provided high‑quality cooling solutions for more than 70,000 customers.

Honors Affirmed

KANSA Refrigeration Awarded the Shanghai High‑Tech Achievement Transformation Certificate

Recently, KANSA Refrigeration’s independently developed“Water‑Cooled Industrial Chiller” (Project No.: 202505611)stood out among numerous projects and successfully obtained the “Shanghai High‑Tech Achievement Transformation Project Certificate” issued by the Shanghai Municipal Science and Technology Commission.

This achievement not only reaffirms KANSA Refrigeration’s R&D strength but also marks a solid and crucial step forward in our journey to transform cutting‑edge technology into practical productivity and drive the industrial refrigeration industry toward high‑end and intelligent upgrading.

Breaking Through

High‑Precision Innovation Addressing Industry Pain Points

As global manufacturing upgrades, temperature control equipment is facing unprecedentedly high requirements. In advanced fields such as semiconductor manufacturing, biopharmaceuticals, and precision optics, production stability and product yield often depend on temperature fluctuations as precise as ±0.05℃. Traditional chillers have shown limitations in temperature control accuracy, energy consumption, and wide‑temperature adaptability, creating a market demand for more precise, efficient, and reliable solutions.

KANSA Refrigeration’s certified project directly responds to this era’s needs. Our “Water‑Cooled Industrial Chiller” is not a simple product iteration but a comprehensive innovation spanning core algorithms to system architecture.

Core Breakthrough 1: Extreme Temperature Control, Breaking Import Dependence

The project pioneered the “Non‑Stop Refrigerant Flow Control Algorithm,” which dynamically optimizes valve opening based on real‑time operating parameters to precisely match refrigerant flow with instantaneous loads. This achieves an exceptional temperature control accuracy of ±0.05℃ across the entire operating range of -40℃ to 110℃. As the first domestically mature industrial chiller to reach this precision level, it successfully breaks the long‑standing reliance on international brands in high‑end fields such as semiconductor wafer dicing.

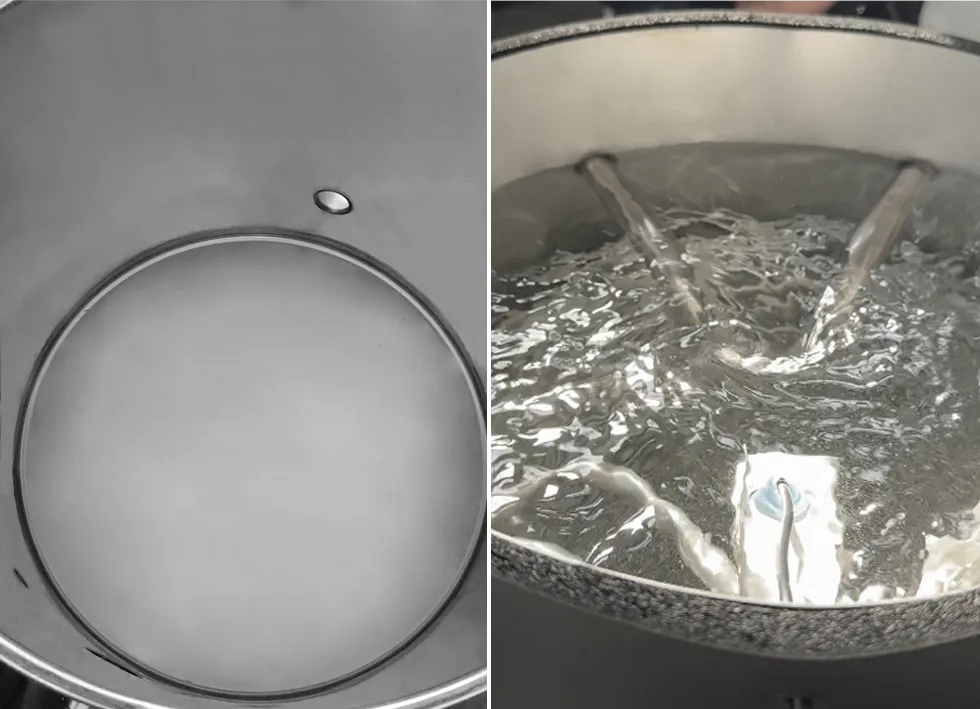

Core Breakthrough 2: Intelligent Coordination, Balancing Efficiency and Stability

We integrated fuzzy PID control technology with an innovative water tank system design. The fuzzy algorithm enhances the system’s adaptability, while the PID algorithm ensures precise adjustment. Combined with circumferentially distributed temperature sensors and a unique flow channel design, the system rapidly eliminates temperature overshoot and achieves a flow control accuracy of ±0.1L/min across a wide flow range of 1–30L/min, ensuring stable operation even at ultra‑high temperature control precision.

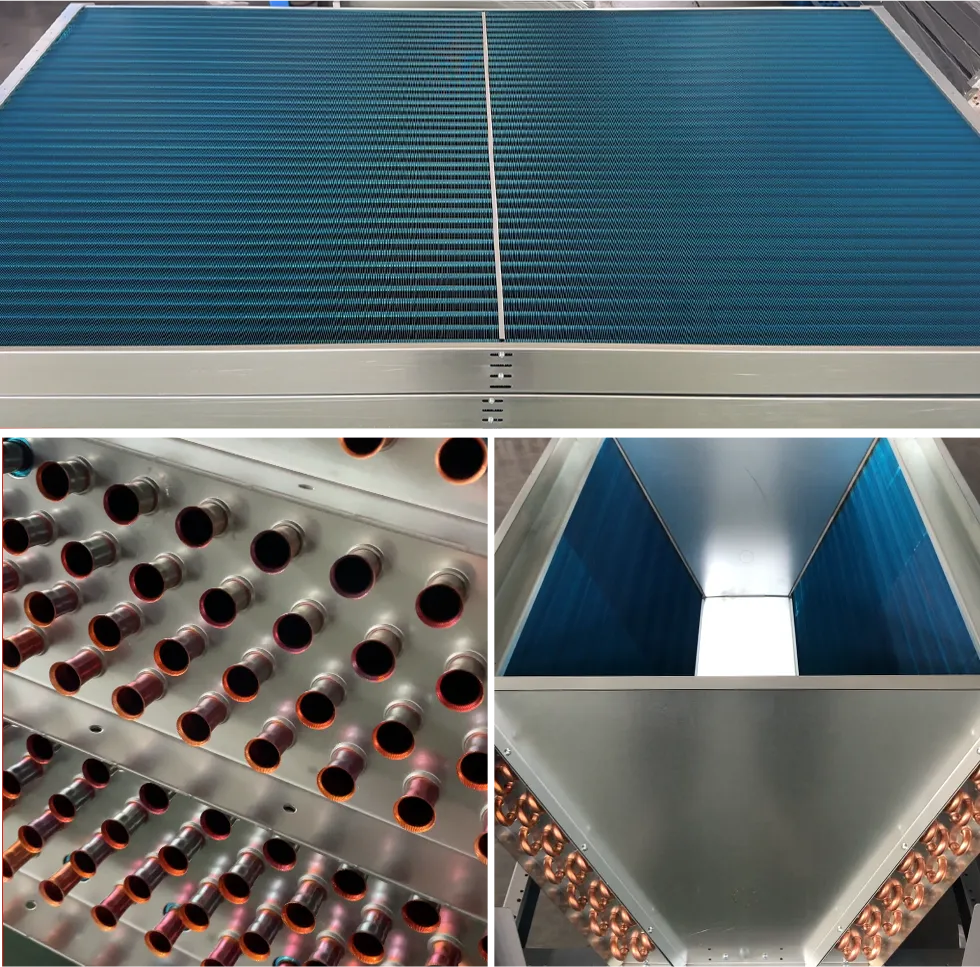

Core Breakthrough 3: High Energy Efficiency, Setting a New Benchmark

Through advanced condensation and integrated refrigeration pipeline technology, the project optimizes the internal structure of the condenser, significantly improving heat exchange efficiency. The final product achieves leading domestic cooling efficiency at the same power level, substantially reducing long‑term operating costs for customers.

Accumulated Strength

A Comprehensive Technological Moat

True innovation is reflected in every detail designed to enhance user value. This project has built a comprehensive technological moat covering core performance, maintenance convenience, and long‑term reliability:

Modular and Easy‑to‑Maintain Design:

Reduces the average repair time to less than 30 minutes. The supporting installation structure effectively reduces vibration and improves heat dissipation, enhancing operational stability.

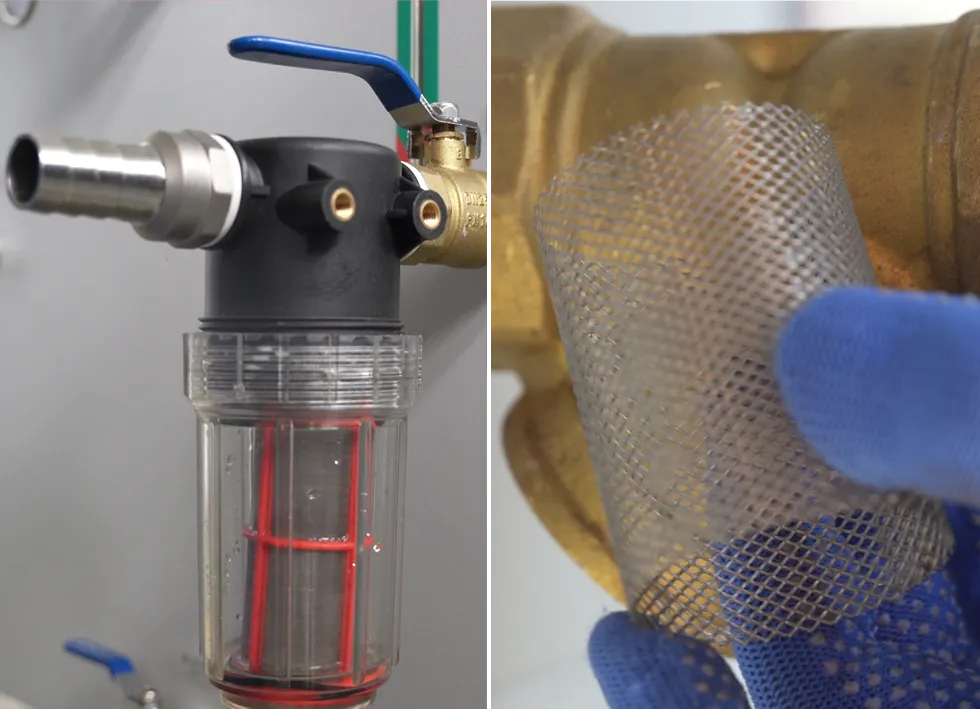

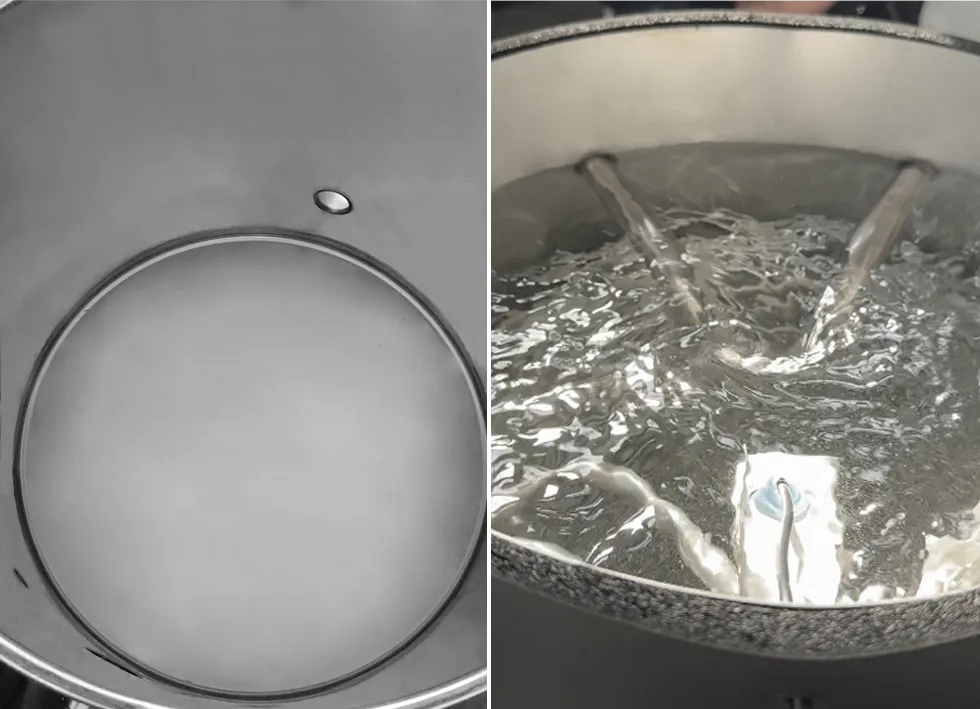

Self‑Cleaning Pre‑installed Structure:

Automatically removes internal fouling, greatly improving maintenance convenience and cleanliness while ensuring long‑term performance.

Strong Intellectual Property Foundation:

Related technologies have obtained 2 national invention patents (“A High‑Precision Temperature Control Industrial Chiller” and “An Easy‑to‑Maintain Chiller”) and 2 utility model patents, providing strong IP protection for the product.

After rigorous testing and evaluation by authoritative institutions, the product’s technical level has reached leading domestic and advanced international standards.

Broad Prospects

Empowering Industrial Upgrading and Driving a Green Future

This achievement transformation is not only the realization of technology but also the key to unlocking a vast market.

Precise Market Positioning:

The product targets strategically emerging industries with extreme temperature control requirements, such as semiconductor manufacturing, biomedicine, data centers, and precision electronics. With the expansion of domestic semiconductor production capacity and the wave of localization, the prospects are extremely promising.

Significant Competitive Advantages:

Compared with top international brands, our product achieves equal or higher precision with lower energy consumption, a wider temperature range, and strong cost‑effectiveness. Compared with leading domestic products, we have surpassed key indicators. This gives us powerful import substitution capabilities and strong market competitiveness.

Far‑Reaching Social Benefits:

The industrialization of this project will drive technological upgrades in the upstream supply chain and promote the development of high‑end manufacturing. Its excellent energy efficiency directly helps downstream enterprises reduce energy consumption, supporting the country’s “Dual Carbon” goals. Additionally, the entire chain from R&D to production and sales will create numerous high‑quality jobs, achieving both economic and social benefits.

Technology as the Foundation, Innovation for the Future

Since its establishment in 2006, Shanghai KANSA Refrigeration Equipment Co., Ltd. has been committed to the R&D and innovation of industrial refrigeration technology. The company’s main products include industrial chillers, high‑low temperature integrated machines, cabinet air conditioners, oil coolers, and new innovative products such as new energy temperature control units and immersion‑type cutting fluid coolers. These products are widely used in industries such as industry, new energy, injection molding, food processing, and medical care, and have provided high‑quality cooling solutions for more than 70,000 customers.